Introduction: Embracing the Craft of EDC Knives with the Shieldon

Hierophant

The Surge of EDC Knives in Modern Culture

Every Day Carry (EDC) knives have surged in popularity as symbols of self-reliance and craftsmanship. These compact, functional tools are not just accessories but extensions of one's personal style and preparedness. With a market that's rapidly expanding, enthusiasts are not only keen on owning EDC knives but also on understanding their intricate mechanics.

The Shieldon Hierophant: A Fusion of Art and Utility

Enter the

Shieldon Hierophant, a masterpiece from the creative mind of Matthew Szymanski.

This EDC knife is a seamless blend of utility and aesthetics, designed to cater

to both knife aficionados and daily users. With a 154CM blade known for its

resilience and a double G10 handle that provides a secure grip, the Hierophant

stands as a pinnacle of modern knife-making. The nested liner lock and ceramic

ball bearings ensure smooth deployment, while the design — inspired by Greek

mythology — imbues it with a narrative as rich as its functionality.

Mastery in Maintenance: Disassembly and Reassembly Skills

Understanding

the disassembly and reassembly of the Hierophant isn't just about maintenance;

it's about deepening the connection between the knife and its owner. It's a

skill that transforms users from passive carriers to active participants in the

life of their knife. Disassembling allows for a comprehensive cleaning,

essential upkeep, and the option to customize, making it a critical skill for

any serious EDC carrier.

Through this

article, we'll explore the meticulous process of breaking down and rebuilding

the Shieldon Hierophant. We'll delve into the thoughtful engineering behind

each component, the practical beauty of its design philosophy, and the

satisfying journey from disassembly to a well-earned reassembly. Whether you're

a seasoned collector or a newcomer to the world of EDC, mastering these skills

will elevate your experience beyond the mere act of carrying a knife.

Unveiling the Shieldon Hierophant: Where Elegance Meets Precision

A Crafted Piece of EDC Excellence

The Shieldon

Hierophant, item MS01A from the Crusader segment, is not just any EDC knife;

it's a meticulously crafted tool designed by the renowned Matthew Szymanski.

This knife encompasses balance, strength, and a lightweight design, weighing in

at just 4.27 oz (121g), making it significantly lighter than other knives of

similar size. With a blade forged from 154CM steel, known for its exceptional

edge retention and corrosion resistance, the Hierophant boasts a flat grind and

a satin finish, presenting a perfect blend of performance and visual appeal.

Design Ingenuity of Matthew Szymanski

Matthew

Szymanski's design philosophy marries functionality with a nod to ancient

wisdom, as seen in the Hierophant's name and theme. His approach to using

low-end materials to initially introduce the design to the market is a

testament to Shieldon's confidence in delivering high-end quality. The unique

color palette of honeydew and jade on the G10 handle not only sets this knife

apart aesthetically but also aligns with the Hierophant theme, borrowing its

name and symbolic significance from the Greek myths.

Key Features and Selling Points

The Hierophant's drop point blade is a classic choice for EDC, offering versatility for daily tasks with a 15-20 degree sharpened angle right out of the box. This level of readiness is a testament to Shieldon's commitment to user satisfaction from the first cut. The blade's swedge enhances its beauty and balance, while the satin finish reduces glare, providing a discreet yet stylish appearance.

The double

G10 handle is robust, designed for enduring use, and the nested liner lock

mechanism ensures the blade stays secure when in use. The engineering

thoughtfulness extends to the assembly hardware, using T8 screws for most of

the knife, simplifying maintenance tasks for the user. The pocket clip is

nearly full deep carry, designed for a low profile in the pocket, and is

complemented by the smooth action of a caged ceramic ball-bearing system.

The Hierophant's disassembly and assembly are as elegant as its design, with Shieldon opting for non-glued screws, a decision driven by user feedback for ease of maintenance. Each step, from the strategic placement of the T6 screws to the skeletonized liners for weight reduction, showcases Shieldon's dedication to detailed craftsmanship.

Embrace the

Hierophant for its exceptional design, user-friendly maintenance, and the story

it carries with every slice — a true testament to Shieldon's vision of

combining classic mythology with modern EDC functionality.

Preparing for Disassembly: Laying the Groundwork for Your Shieldon

Hierophant

The Essential Step of Proper Disassembly

Before diving into the intricacies of the Shieldon Hierophant, it's crucial to understand the value of proper disassembly. Disassembling your EDC knife is not just about taking it apart but doing so in a way that ensures every component remains intact and functional upon reassembly. This careful process allows for thorough cleaning, maintenance, and the occasional upgrade, extending the knife's lifespan and keeping it in optimal working condition.

Gathering Your Toolkit

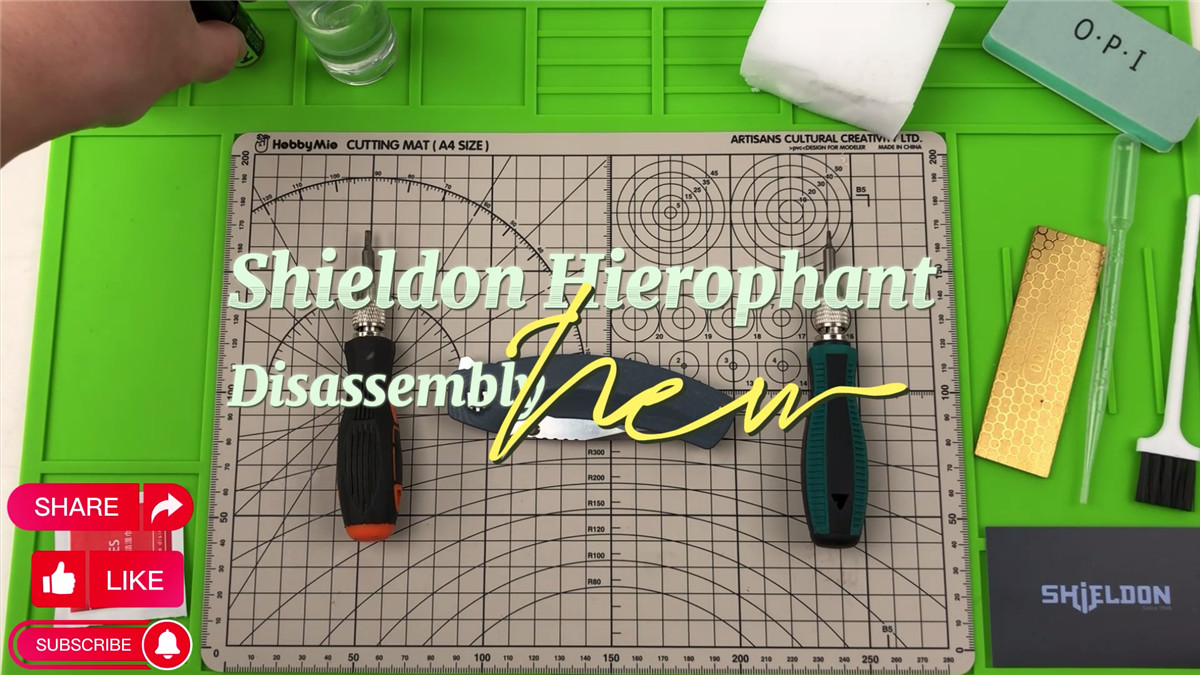

To

disassemble the Shieldon Hierophant, you'll need the right tools for the job.

Thankfully, this knife's design considers the user's convenience; requiring

only two types of screwdrivers for the task — T8 for the main pivot and handle

body, and T6 for the pocket clip. Having the correct tools ensures that you

won’t strip the screws or damage your knife, allowing for a smooth and

efficient maintenance experience.

Considerations and Precautions Before You Begin

Before you start, it's imperative to work in a clean, well-lit area where small parts are less likely to get lost. Ensure your workspace is free from clutter and potential contaminants. Remember that the Hierophant's screws are no longer glued, as per Shieldon's response to consumer feedback, making the disassembly a user-friendly experience. However, it's still vital to proceed with caution to avoid misplacing any components or disrupting the delicate balance of the assembly.

When

disassembling your knife, be mindful of the blade's edge. The Hierophant's

154CM steel blade is sharpened to a 15-20 degree angle, offering superb

out-of-the-box usability that you'll want to maintain. Take care not to dull

the edge as you work. Approach each step with respect for the design and

craftsmanship that Matthew Szymanski has instilled in this tool — from its

lightweight, durable double G10 handle to its smooth ceramic ball-bearing

deployment mechanism.

In preparing to disassemble your Shieldon Hierophant, you're not just taking apart a knife; you're engaging with a process that's as much about care and precision as it is about practicality. It's an opportunity to appreciate the knife's design, reflect on its symbolic connection to Greek mythology, and ensure you're equipped to keep your Hierophant in peak condition for years to come.

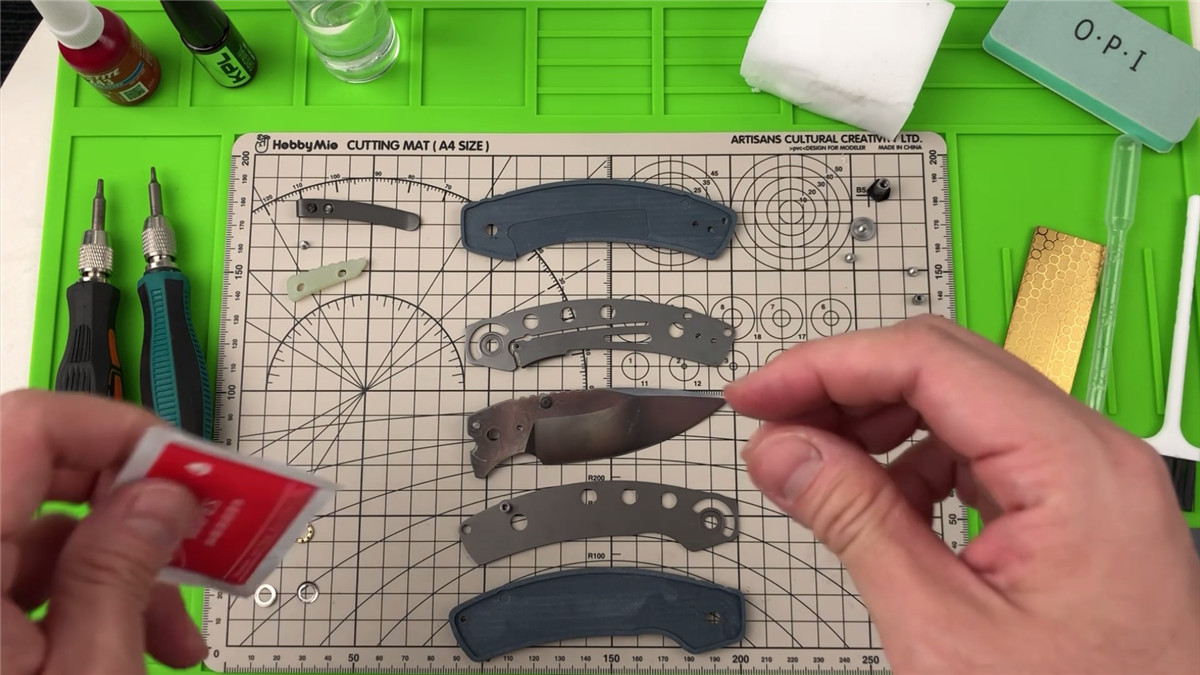

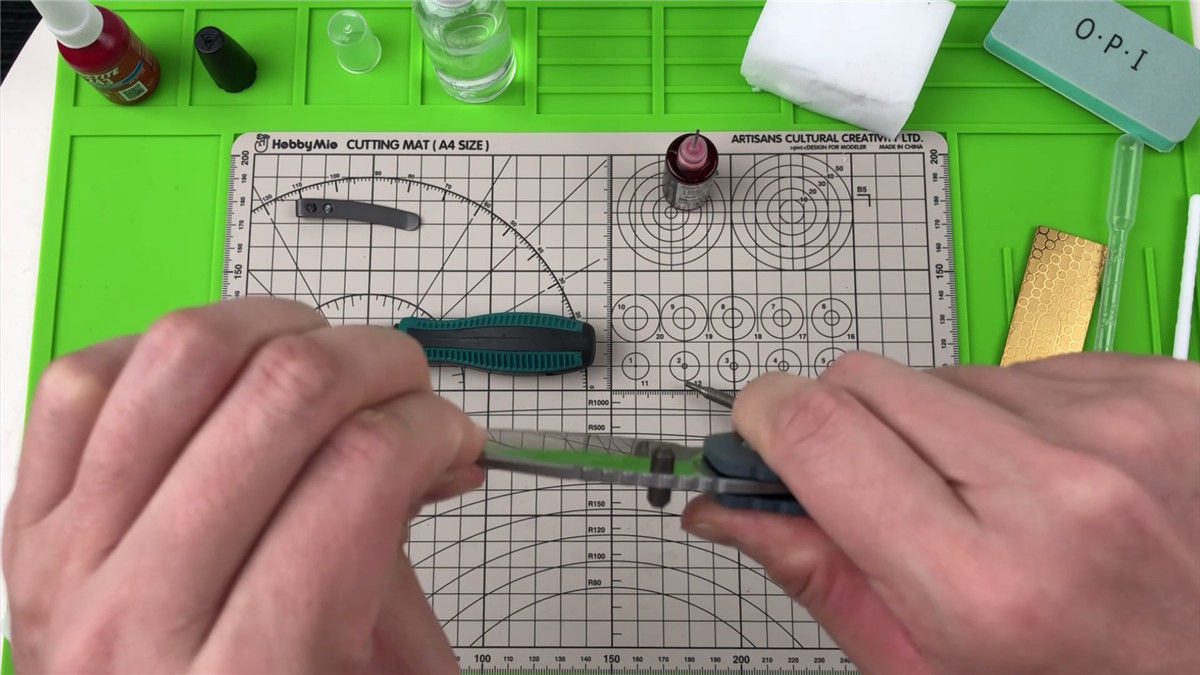

Step-by-Step Disassembly Process of the Shieldon Hierophant

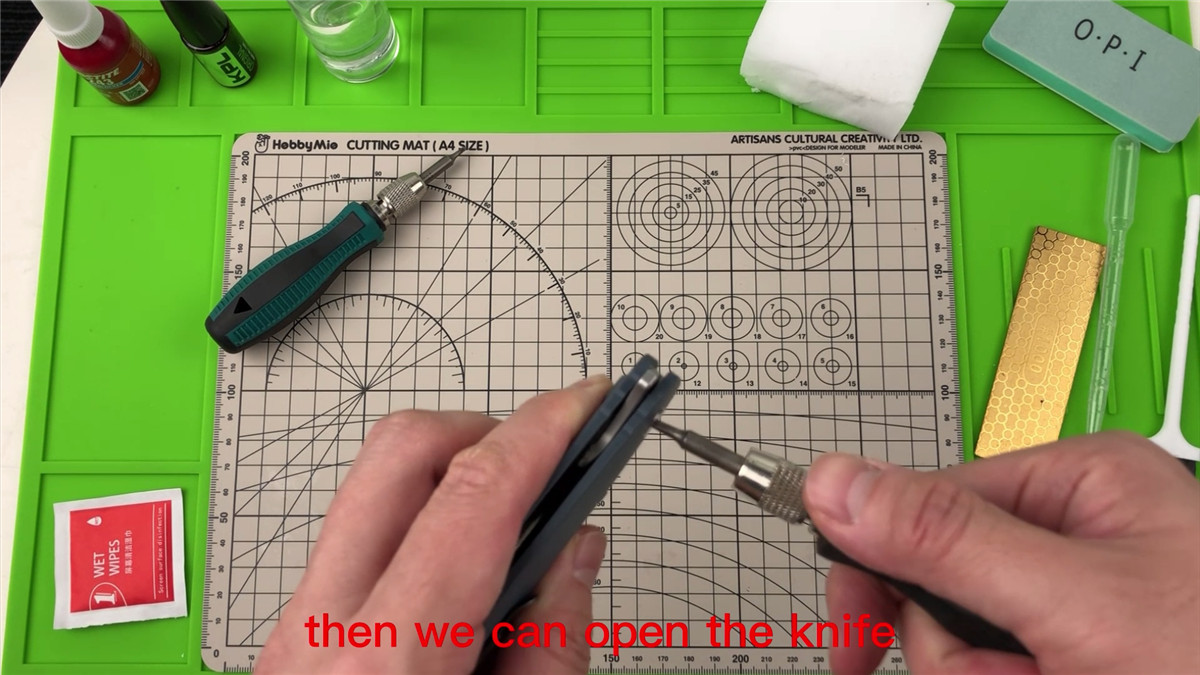

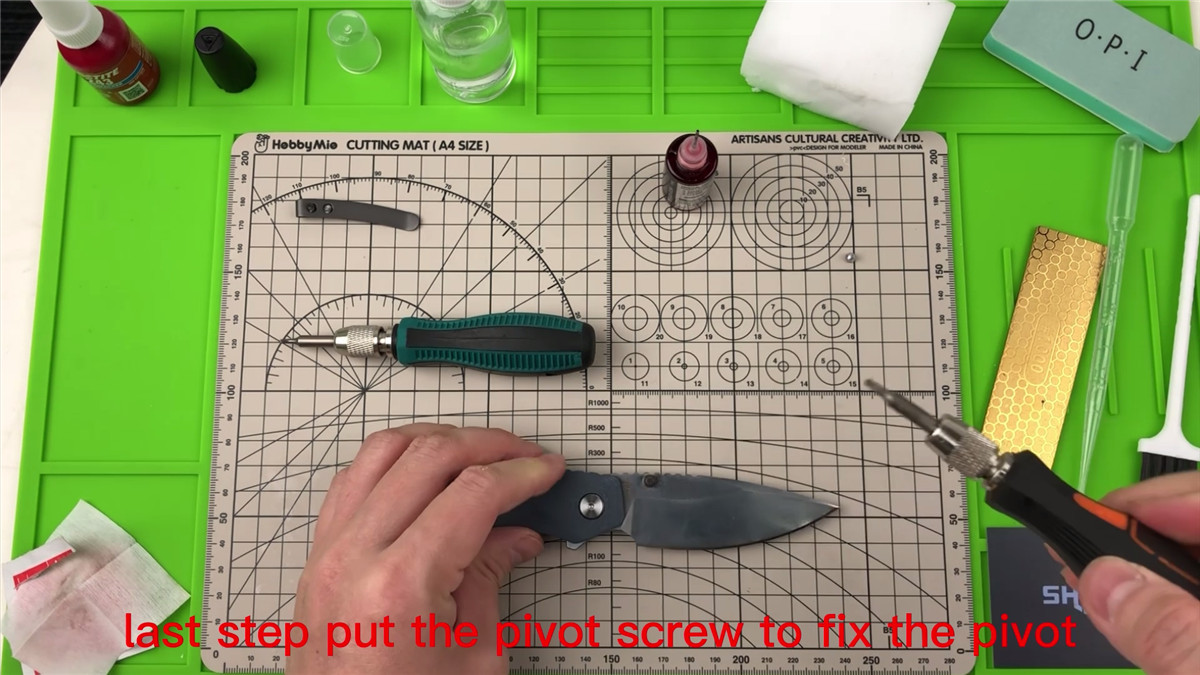

Mastering the Pivot Screw: Techniques for Success

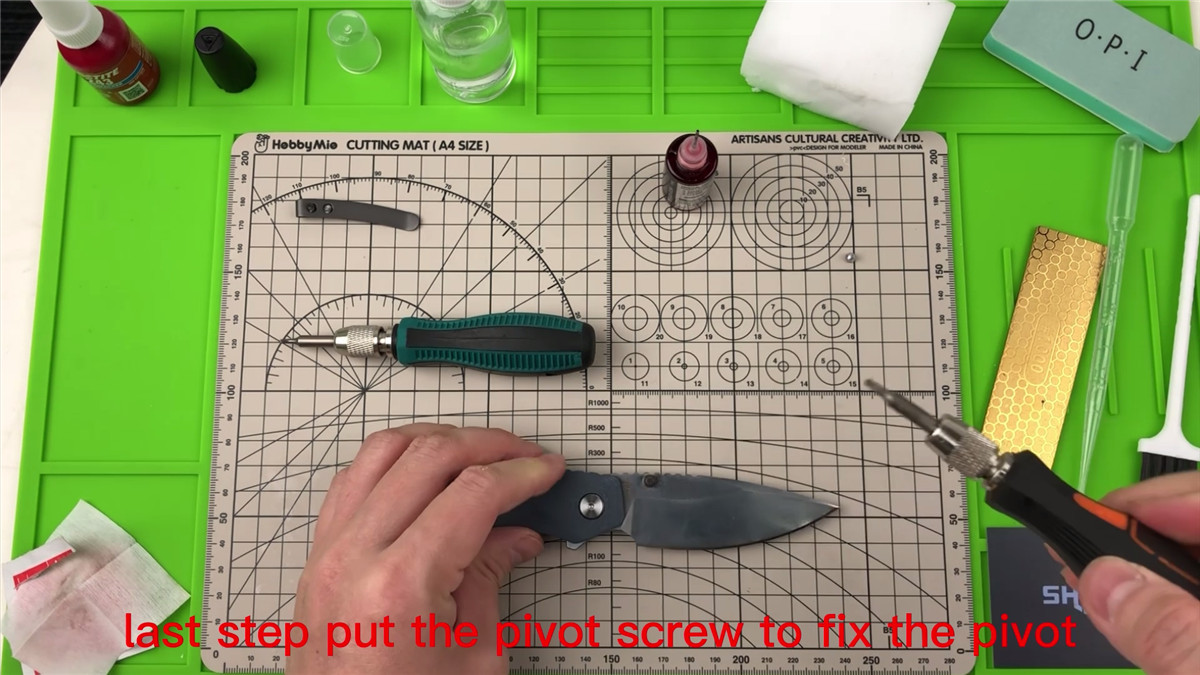

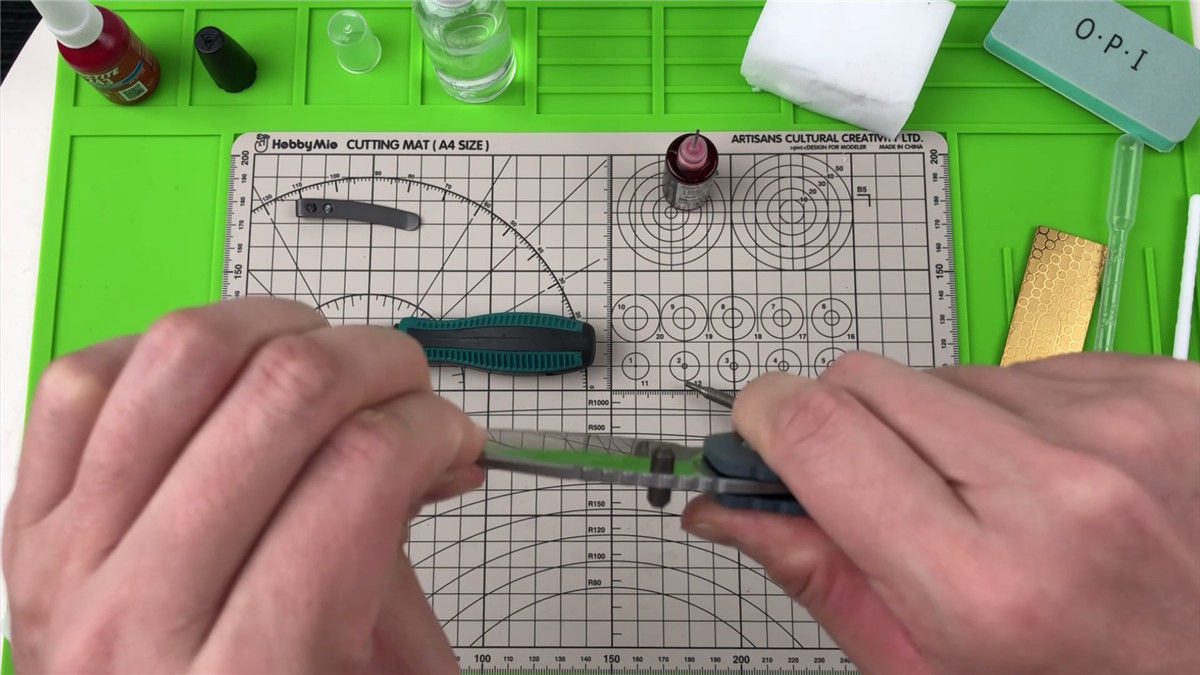

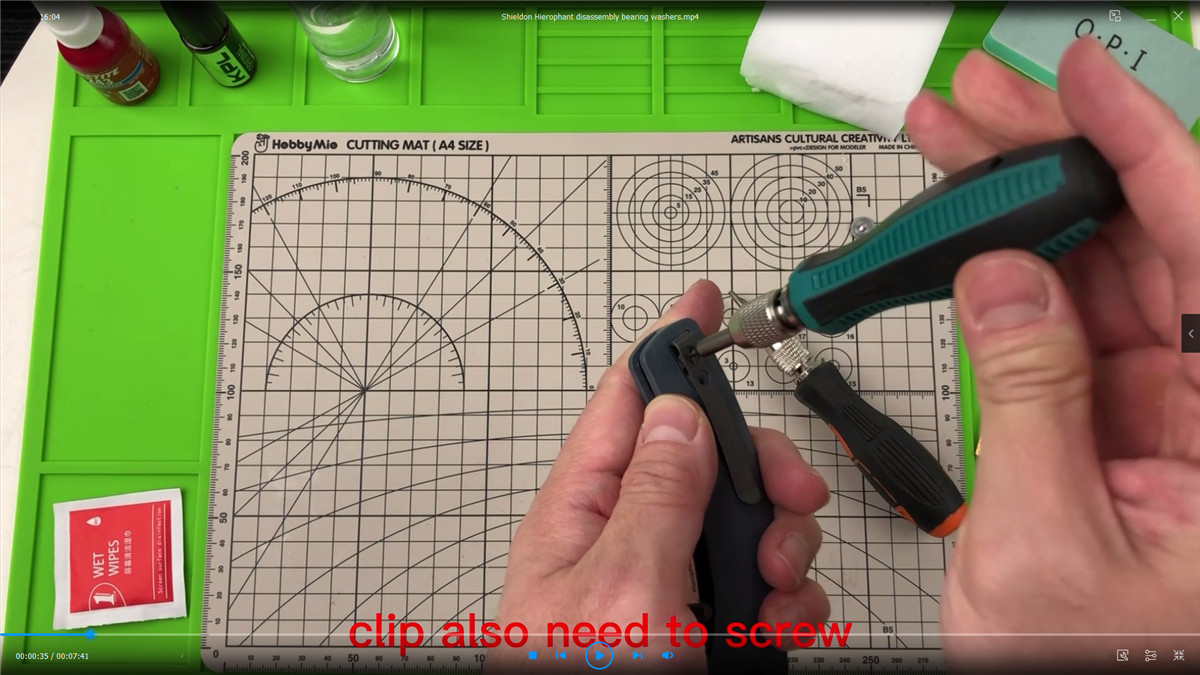

The pivot

screw is the linchpin of the Shieldon Hierophant's folding mechanism, and its

unscrewing is a crucial first step in the disassembly process. Armed with a T8

screwdriver, approach this task with precision. Here's a pro-tip: apply gentle

pressure and turn slowly to avoid stripping the screw. The pivot should be

unscrewed before addressing any other hardware, as this will ensure the blade

and handle are not under tension, reducing the risk of accidental injury or

damage.

The 'Shield'-Like Screw and Its Unique Design

Designed to prevent the pivot from rotating during maintenance, the 'shield'-like screw on the showside is an innovative feature that sets the Hierophant apart. This design ensures that the screw on the reverse side remains stationary, allowing for a hassle-free disassembly. It's a testament to Shieldon's commitment to user-friendly products, echoing the thoughtful design philosophies of Matthew Szymanski.

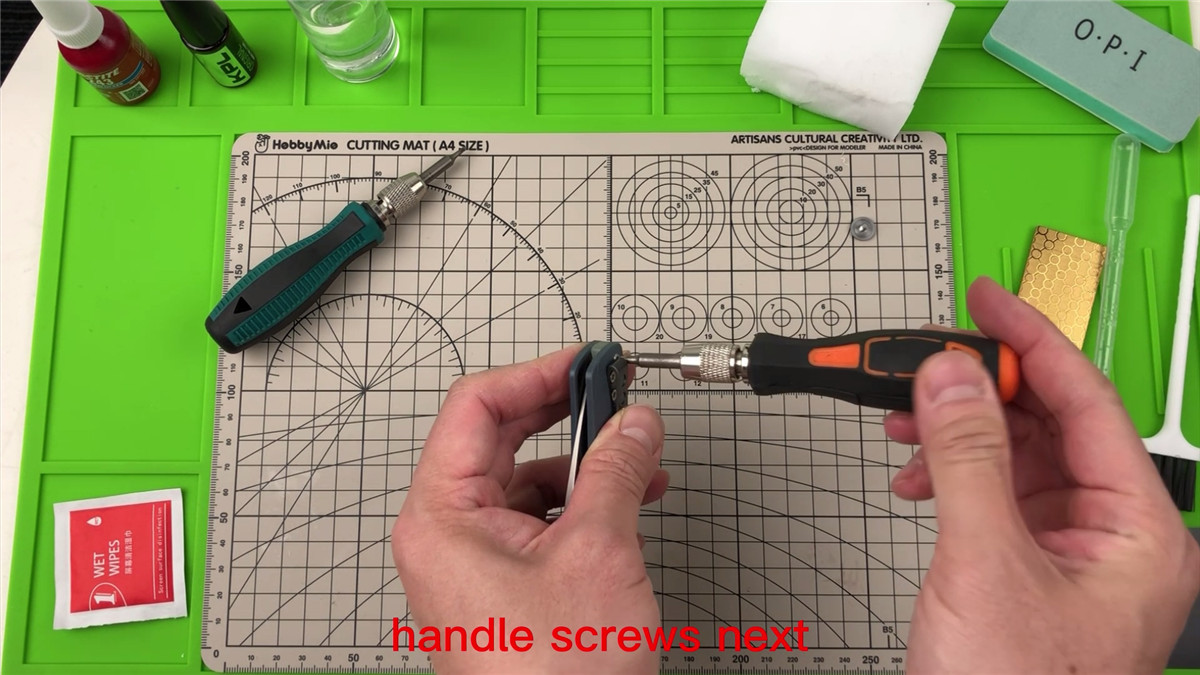

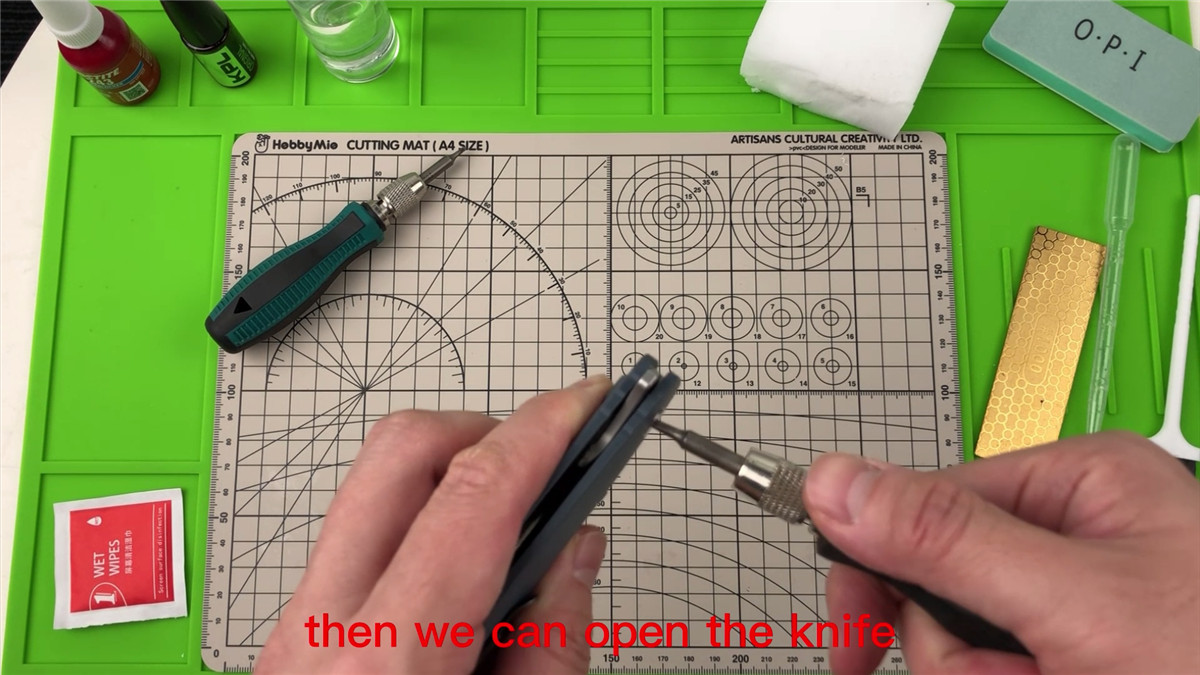

The Elegant One-Screw Handle Design

Simplicity

is the essence of elegance, and the Hierophant embodies this with its one-screw

handle design. By using a single T8 screw on the handle, Shieldon has not only

created a sleek and minimalist aesthetic but also made maintenance an absolute

breeze for knife enthusiasts. This single screw architecture streamlines the

disassembly process, making it straightforward for owners to maintain their

Hierophant.

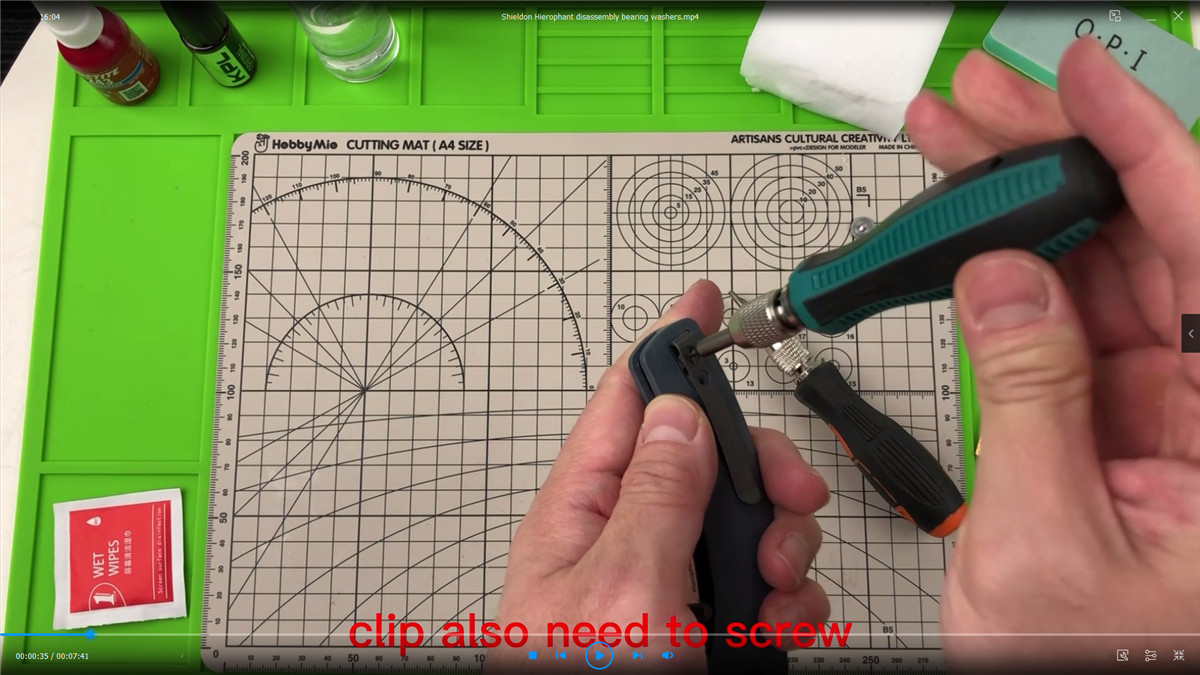

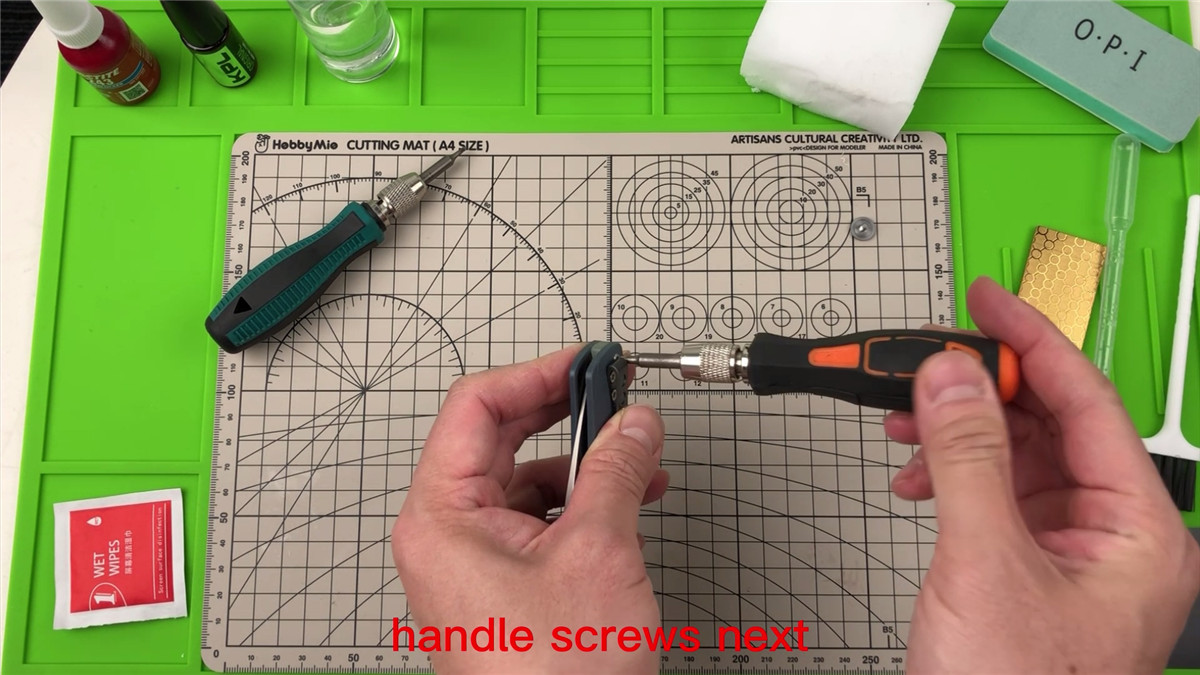

The Dual Functionality of T6 Screws

The T6 screws on the Shieldon Hierophant are a marvel of multifunctional design. While primarily securing the pocket clip, these screws also play a crucial role in attaching the liner to the handle. This dual-purpose approach minimizes the number of screws visible on the knife, maintaining the clean lines of the design and reducing potential weak points. It's a demonstration of Shieldon's commitment to efficient design and functionality, blending form with function in a way that resonates with the practical needs of EDC users.

The

disassembly of the Shieldon Hierophant is a journey through the meticulous

design and high-end craftsmanship of this EDC knife. With each screw and

component, users engage with the thoughtfulness put into the knife's creation.

By following these steps attentively, knife enthusiasts not only learn about

their tool's inner workings but also gain a deeper appreciation for the

expertise behind its assembly. Whether preparing for routine maintenance or

deep cleaning, these techniques ensure that your Hierophant remains a reliable

and elegant companion for all your daily adventures.

Exploring the Inner Workings of the Shieldon Hierophant

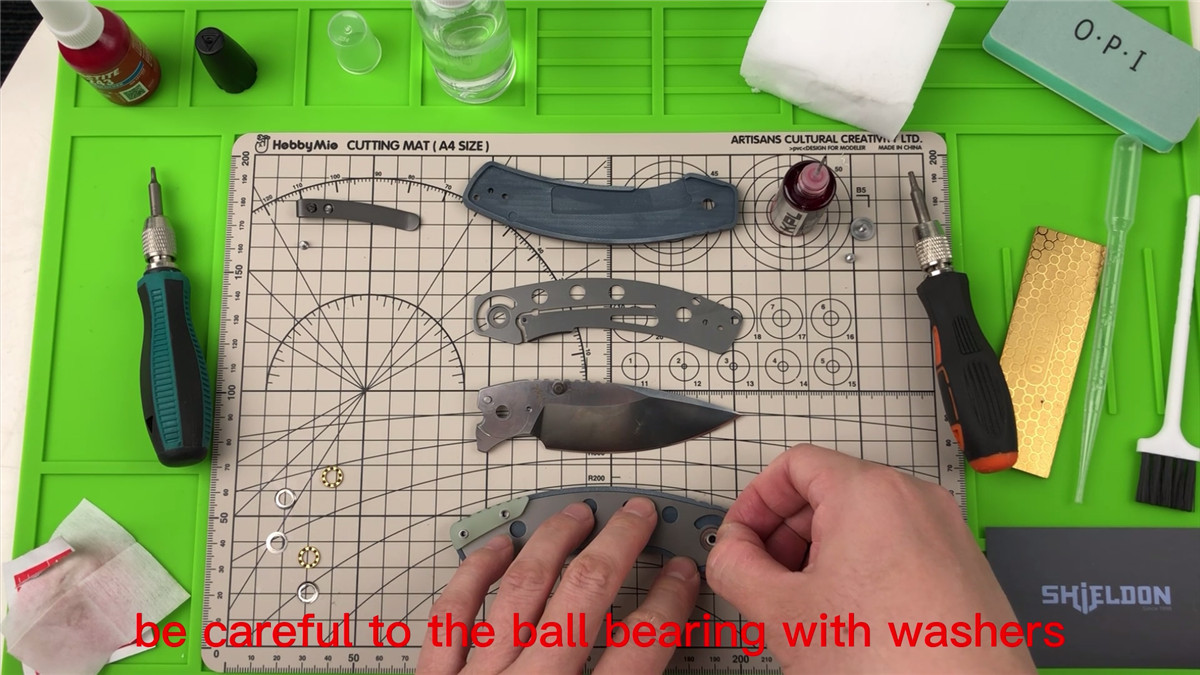

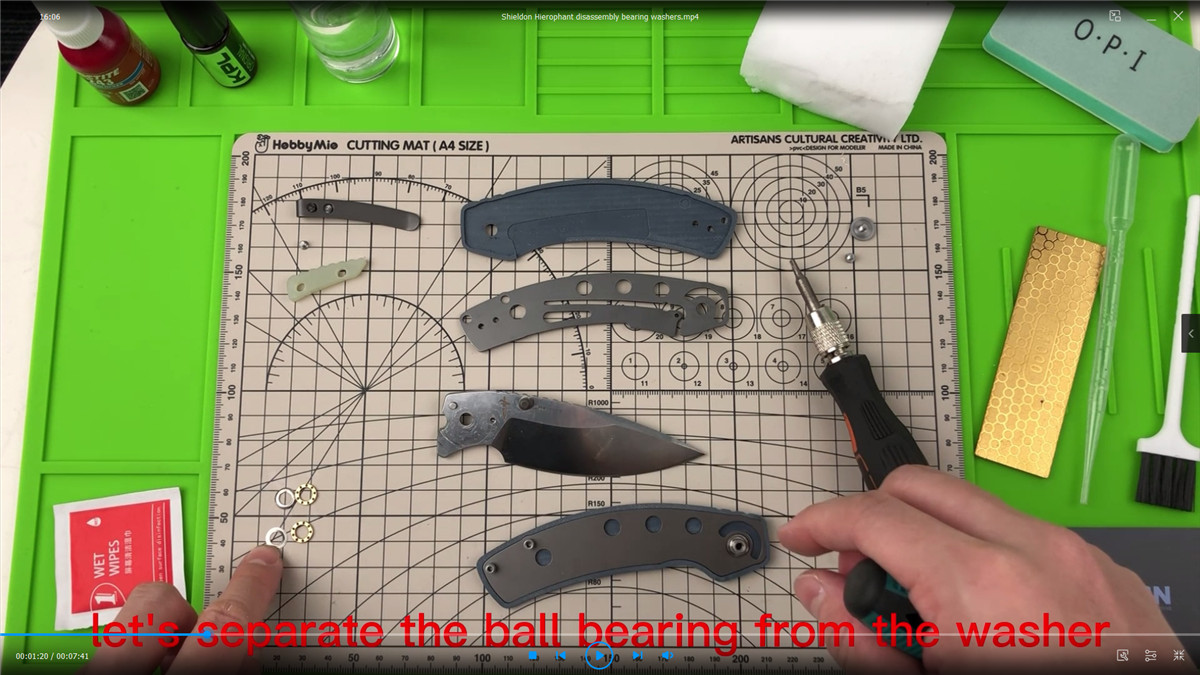

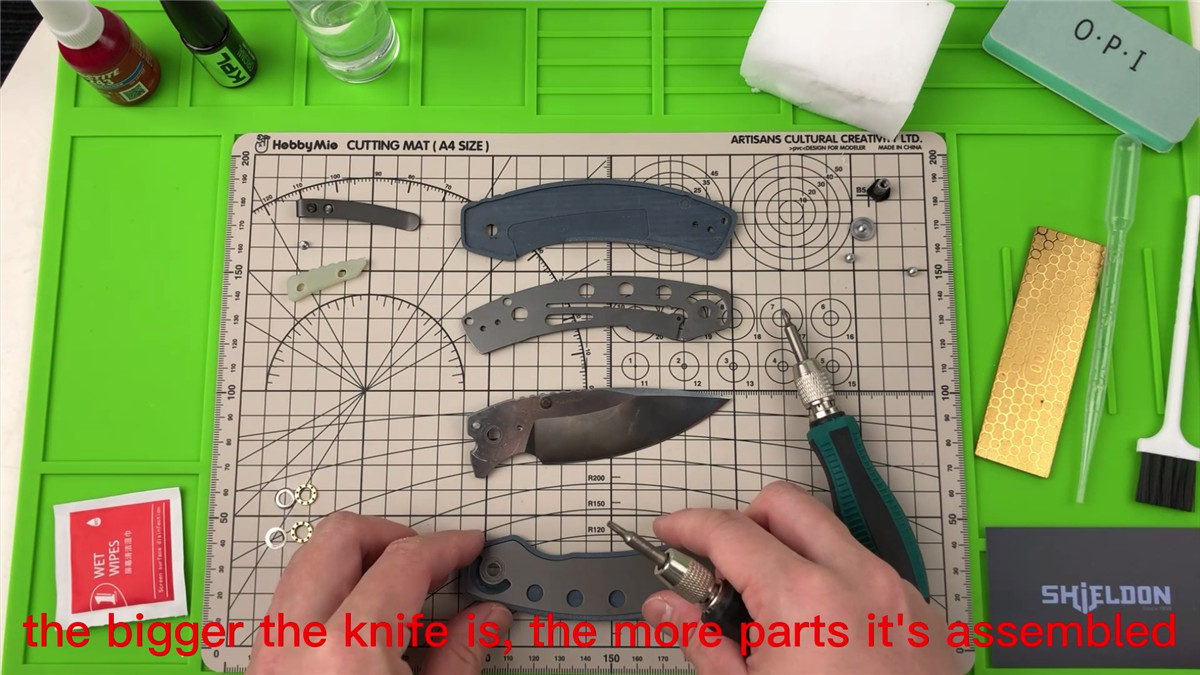

Delving into the Core: Liners, Bearings, and Backspacer

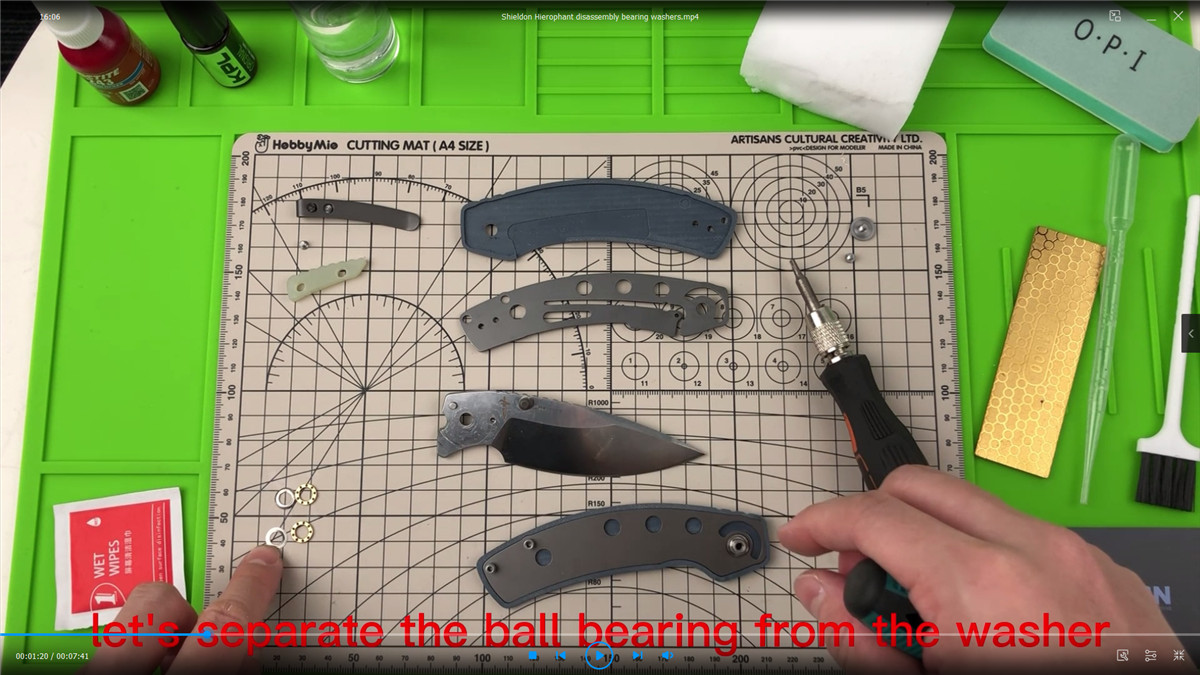

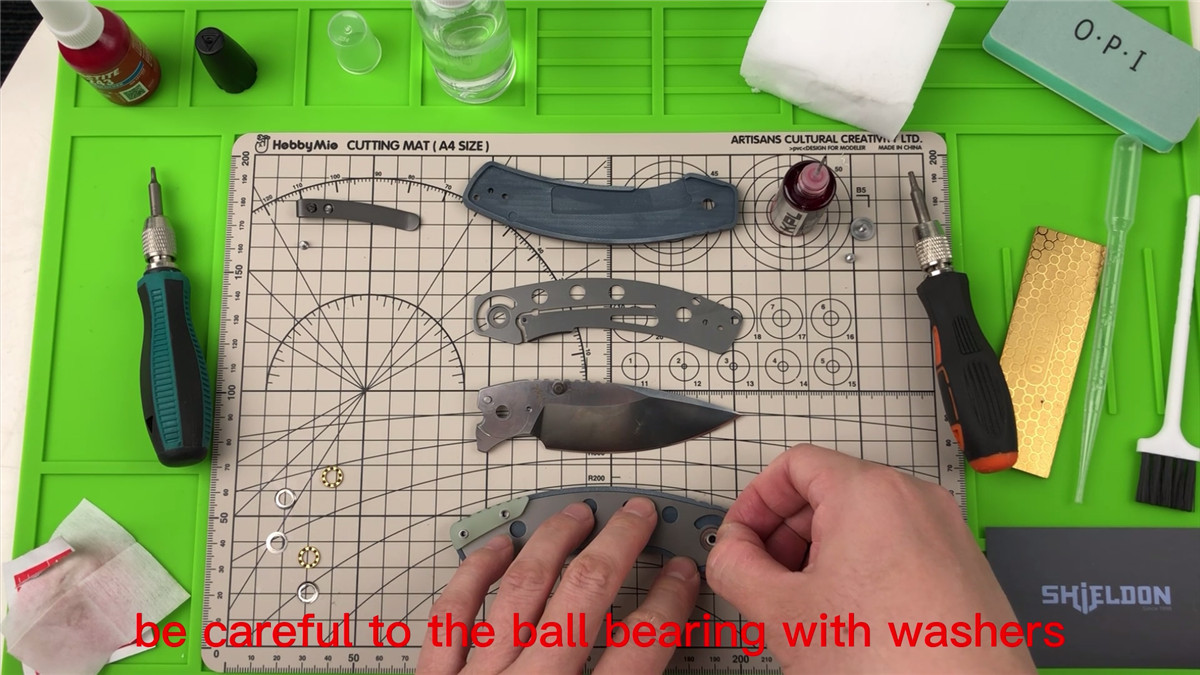

Once you unscrew the Hierophant's pivot and handle, you'll expose the intricate world inside. The skeletonized liners, a product of careful engineering, are vital for structural integrity while minimizing weight—a feature that contributes to the Hierophant's featherlike presence in your pocket. These liners are cut from 3Cr13 steel and treated to a hardness of 42-44 HRC, ensuring durability without unnecessary heft.

The caged

ceramic ball bearings are another highlight of Shieldon's design prowess. They

allow for a fluid, three-way deployment that's as satisfying to use as it is to

watch. And when it's time for reassembly, remember the tiny washers on either

side of these bearings protect your knife's pivot from wear over time, a subtle

nod to longevity in Shieldon's design ethos.

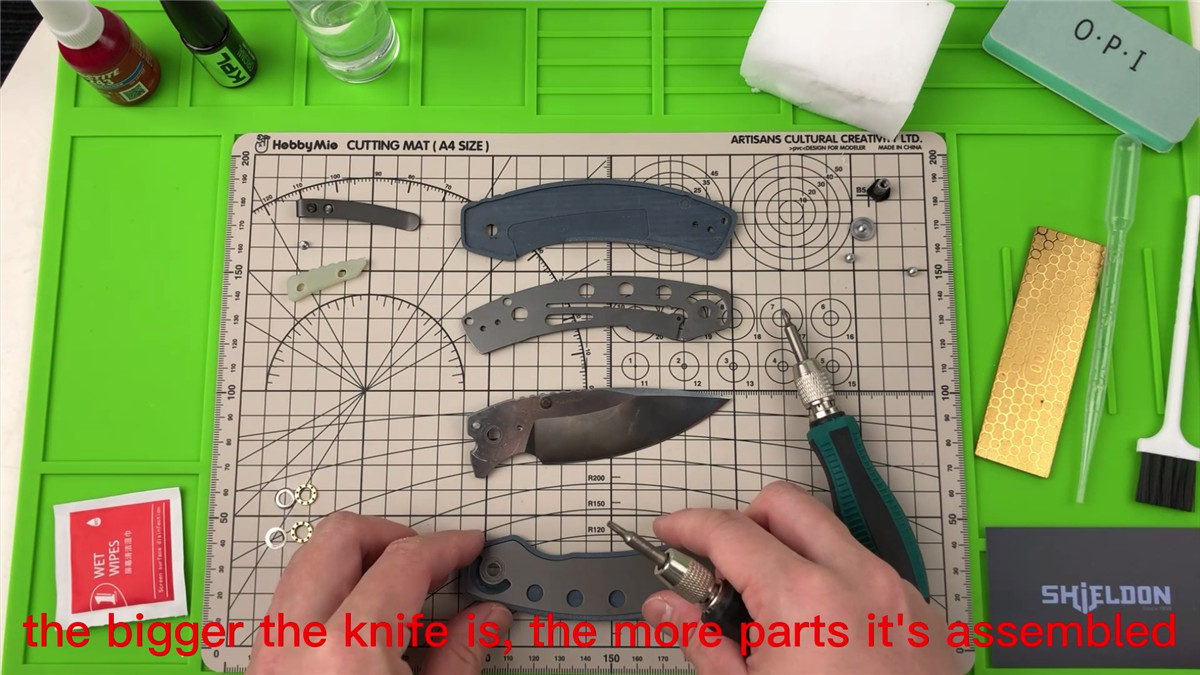

The Balancing Act: Weight and Material Selection

When handling the Hierophant, its lightweight nature is immediately apparent, tipping the scales at just 4.27 oz (121g). This is no accident but the result of deliberate choices in materials and design, such as the four weight-reduction holes in the liners. Each hole shaves off approximately 2g, contributing to the knife's overall nimbleness. It's this kind of attention to detail that defines the Shieldon Hierophant and sets it apart from its peers.

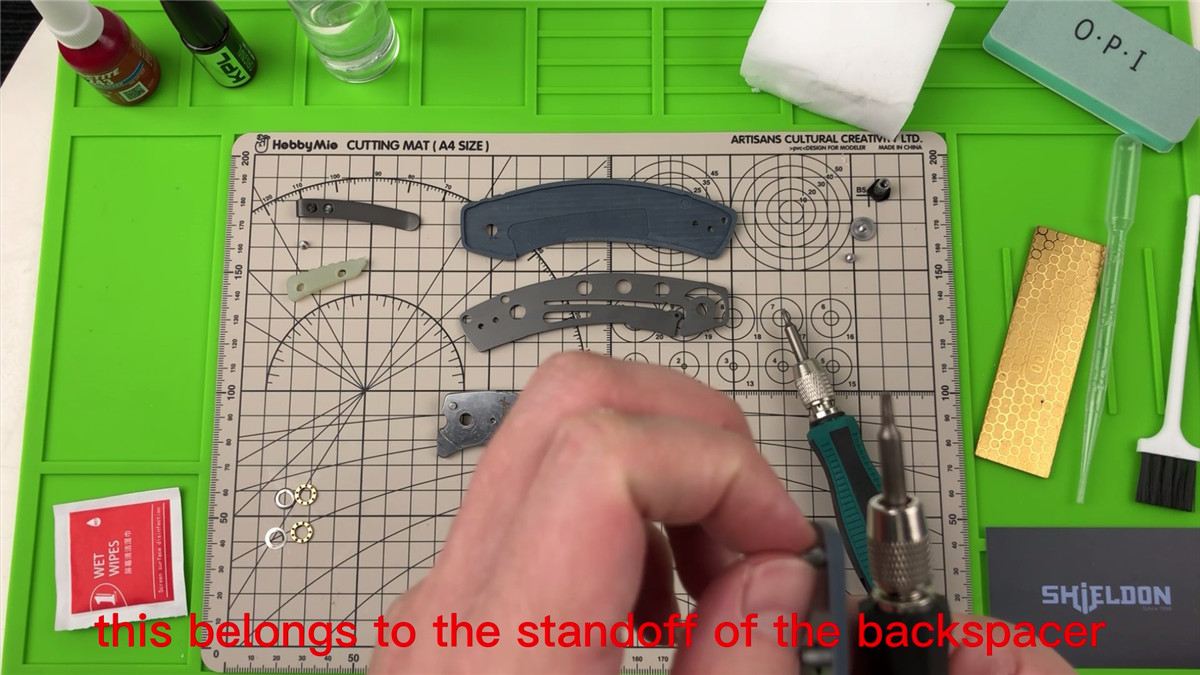

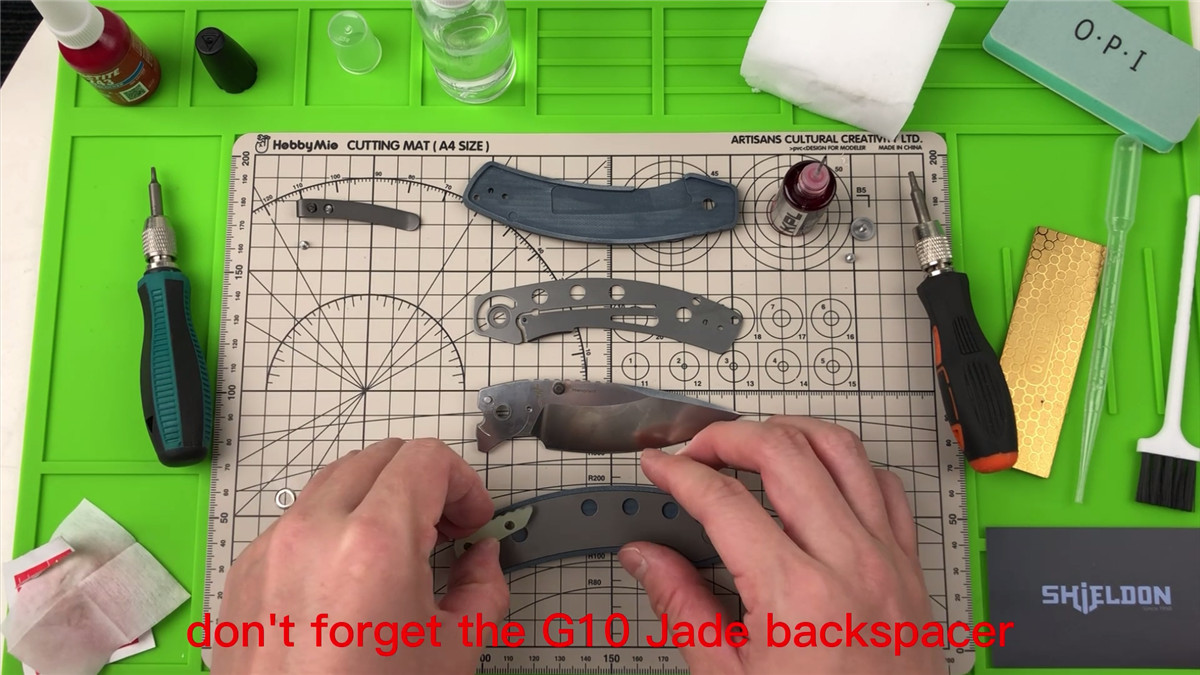

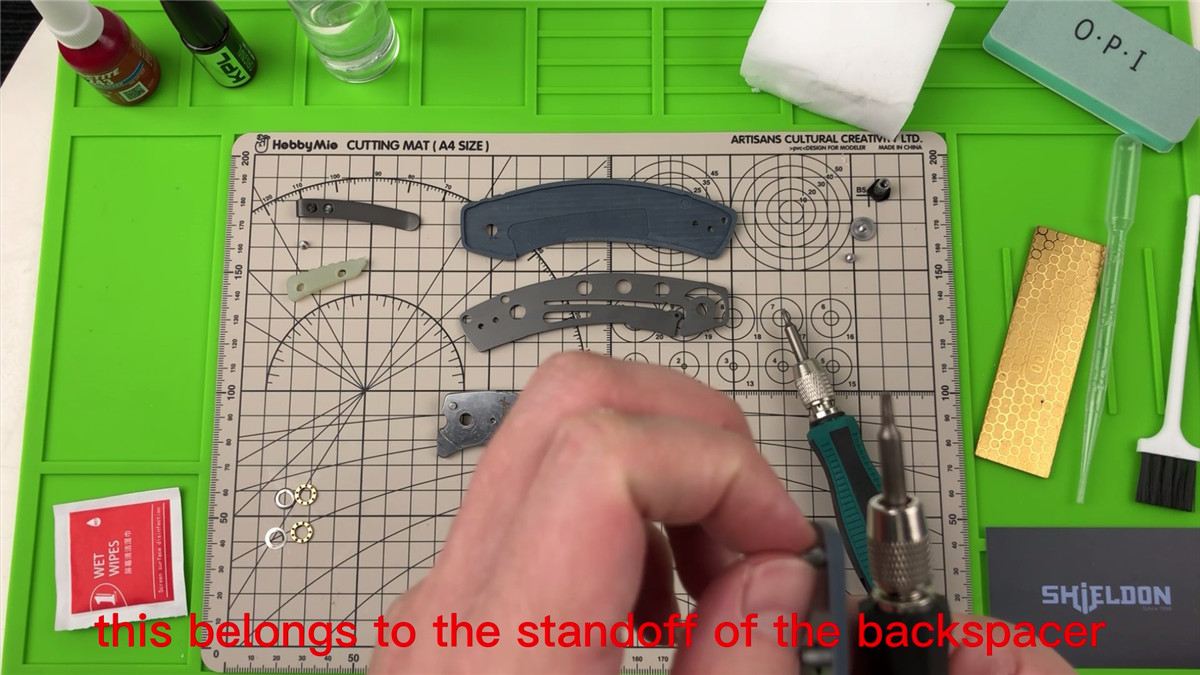

The Backbone of Stability: The Role of Standoffs

Venturing

further into the Hierophant's anatomy reveals the robust standoffs, providing a

standoff between the handle scales even when the Jade G10 backspacer is

removed. These standoffs are constructed from 416 steel, chosen for its

strength, and contribute to the knife's solid feel in hand. They are the unsung

heroes of the knife's stability, ensuring that the integrity of the knife's frame

is uncompromised, regardless of the backspacer's presence.

In exploring the interior of the Shieldon Hierophant, one not only gains insight into the knife's functional aspects but also uncovers the narrative of its construction. The careful balancing of weight, the strategic choice of materials, and the thoughtful inclusion of standoffs—all speak to Shieldon's dedication to creating not just a cutting tool but a piece of EDC artistry. As you learn to dismantle and reassemble this knife, you become part of its story, a testament to the harmony between user and tool.

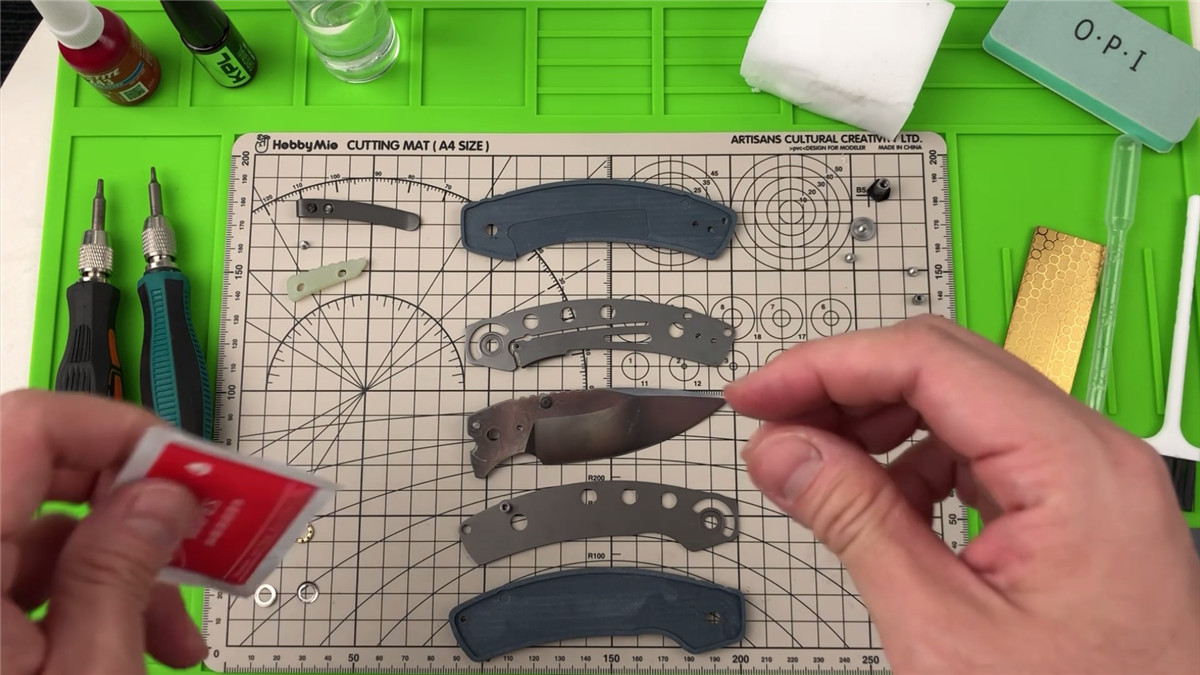

Disassembly: A Closer Look at the Components of the Shieldon Hierophant

Diving Deep into Each Element

When you

disassemble the Shieldon Hierophant, you're not just taking apart a knife; you

are uncovering the meticulous craftsmanship of each component. Starting with

the 154CM blade, a premium steel known for its remarkable edge retention and

corrosion resistance, you can appreciate the flat grind which offers an ideal

balance between sharpness and strength. This blade, enhanced by a drop point

and a subtle swedge, is not only functional for EDC tasks but also resonates

with the knife's aesthetic appeal.

The double G10 handle, known for its durability and excellent grip, is a significant contributor to the Hierophant's lightweight profile. Its honeydew and jade colors are not just distinctive design choices; they also provide a visual representation of the Hierophant's divine inspiration. The nested liner lock within this handle is a testament to Shieldon's commitment to safety and efficiency.

Significance in Everyday Carry Utility

Each part of

the Hierophant is designed with EDC utility in mind. The main pivot hardware,

accessible with a T8 screwdriver, is a crucial point for the knife's smooth

operation, allowing for flipper or thumb stud deployment. The inclusion of

caged ceramic ball bearings ensures this action remains as smooth on the

thousandth open as it was on the first.

The deep carry tip-up pocket clip design is not an afterthought; it's a feature that enhances the practicality of carrying the knife discreetly and securely. The clip's half deep carry design, a unique innovation from Shieldon, addresses a common concern among EDC users, ensuring that the Hierophant can be quickly and comfortably accessed when needed.

Understanding the Role of Each Part

Every screw,

liner, and standoff has its role. The T6 screws serve dual functions, securing

both the pocket clip and the liner, a clever design choice that simplifies the

knife’s profile without sacrificing functionality. Upon disassembly, the

significance of these screws becomes clear, showcasing the designer's attention

to detail and practical innovation.

The backspacer, which may seem like a mere aesthetic addition, plays a crucial role in maintaining the structural spacing between the handle scales. Even the standoffs, though small, are pivotal in preserving the knife's stability and ensuring that the knife remains functional and reliable, no matter the conditions.

Disassembling

the Hierophant not only provides you with the skills to maintain and clean your

knife but also offers a deeper appreciation for each element and its role in

the overall performance and utility of the knife. Shieldon’s Hierophant is a

masterpiece of EDC design, where each component is a piece of the puzzle that

creates an exceptional everyday carry experience. Through this detailed

examination, enthusiasts and users alike can recognize the profound thought and

expertise that goes into constructing a knife that's not only a tool but a

partner in the daily adventures of life.

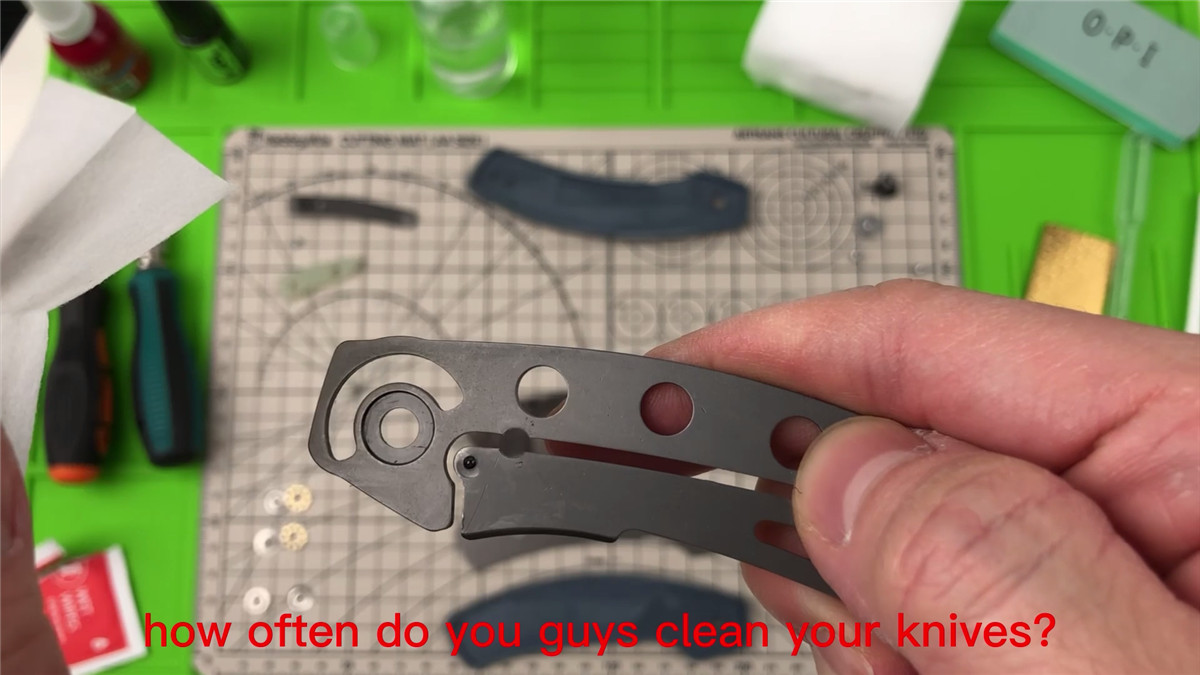

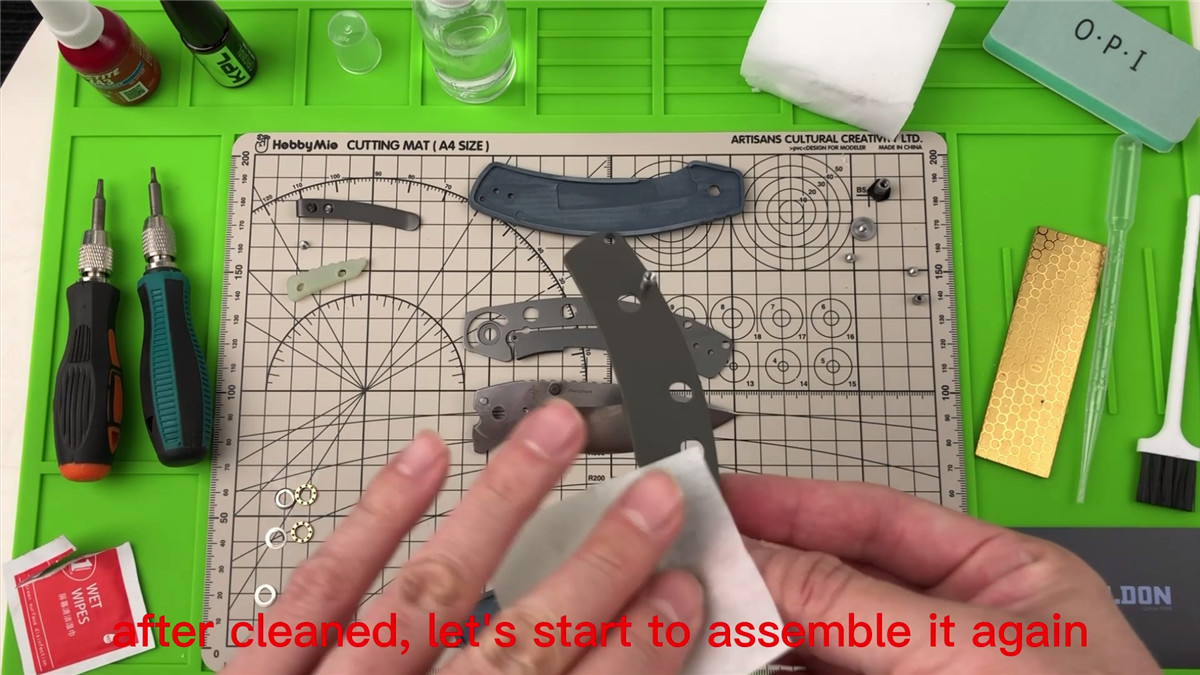

Cleaning and Maintenance of the Shieldon Hierophant

Ensuring Longevity Through Proper Techniques

Maintaining your Shieldon Hierophant isn't just about keeping it looking good—it's crucial for ensuring its longevity and functionality. For a thorough clean, begin by wiping down the 154CM blade, famed for its edge retention, with a soft cloth and a mild detergent. Use a brush to gently scrub the satin-finish surface, being careful to preserve the lines on the bevel that reduce glare and enhance the knife's aesthetics.

The Double

G10 handle, notable for its two-tone honeydew and jade colorway, demands a

careful approach. Dirt can be removed from the textured surface with a

toothbrush or a specialized cleaning tool designed for G10 material. This

prevents buildup that could compromise grip over time.

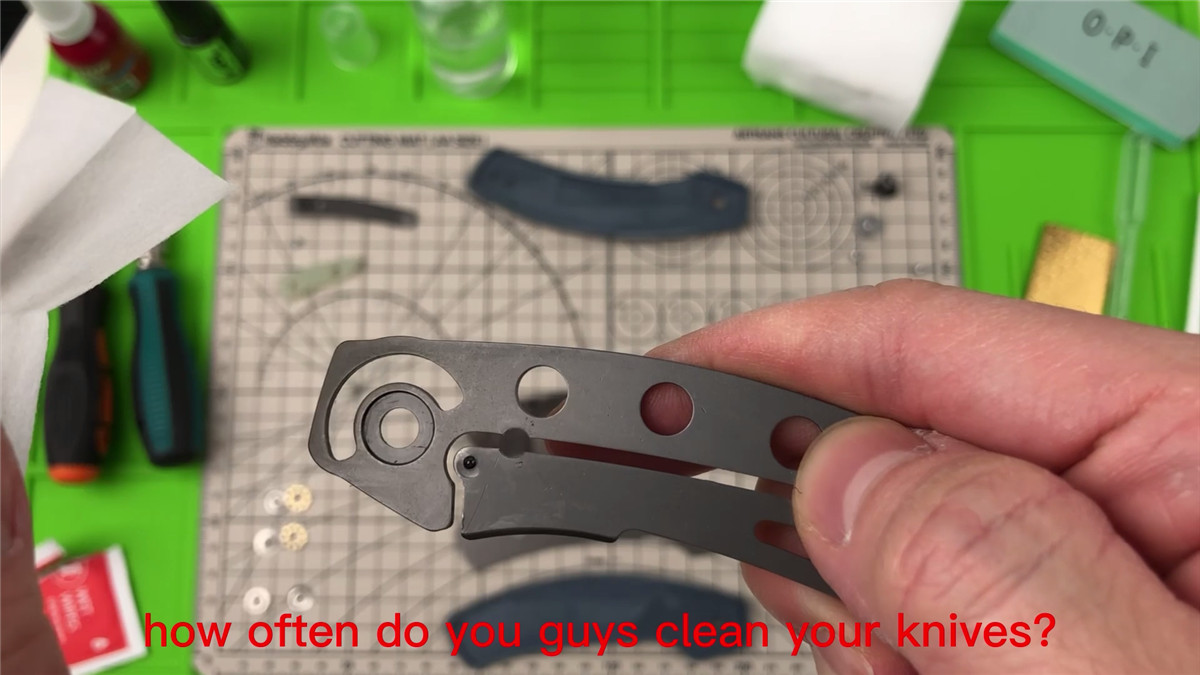

Frequency and Importance of Knife Care

A common query among EDC enthusiasts is the frequency of maintenance. The Hierophant, with its nested liner lock and ceramic ball bearings, should ideally be cleaned every three months or more depending on usage. Regular care prevents grime accumulation and ensures each deployment is as smooth as the first—a cornerstone of the Hierophant's design by Matthew Szymanski.

Products to Keep Your Hierophant in Top Condition

When it

comes to products for keeping your Hierophant in optimal condition, consider

investing in quality lubricants like KPL (Knife Pivot Lube) to maintain the

smooth action of the ball bearings. For the blade, a high-quality knife oil can

prevent rust and corrosion, especially after cleaning with water.

For the handle, a G10 cleaner can restore the grip's texture and color vibrancy. Tuf-Glide or Loctite can be used on screws post-cleaning to ensure they stay in place without being overly tight. Furthermore, a rust inhibitor such as Rusty's Rags can protect the blade when the knife is stored for extended periods.

Regular

maintenance is an opportunity to understand your Hierophant's workings

intimately. Each screw, pivot, and clip is a testament to Shieldon's dedication

to quality, and by caring for these components, you honor the craftsmanship and

ensure that your knife stands the test of time and use. The Hierophant isn't

just a tool—it's a companion on your daily adventures, and with proper care, it

will remain reliable and efficient, much like the wisdom of its namesake, the

Hierophant of Greek myth.

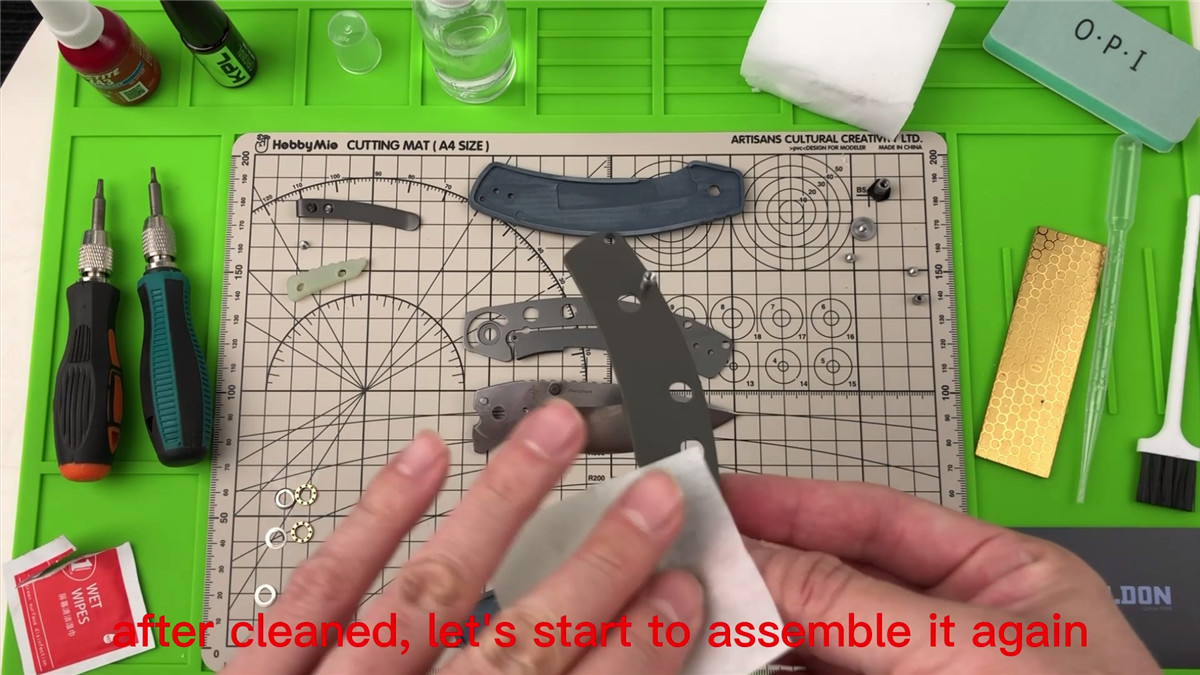

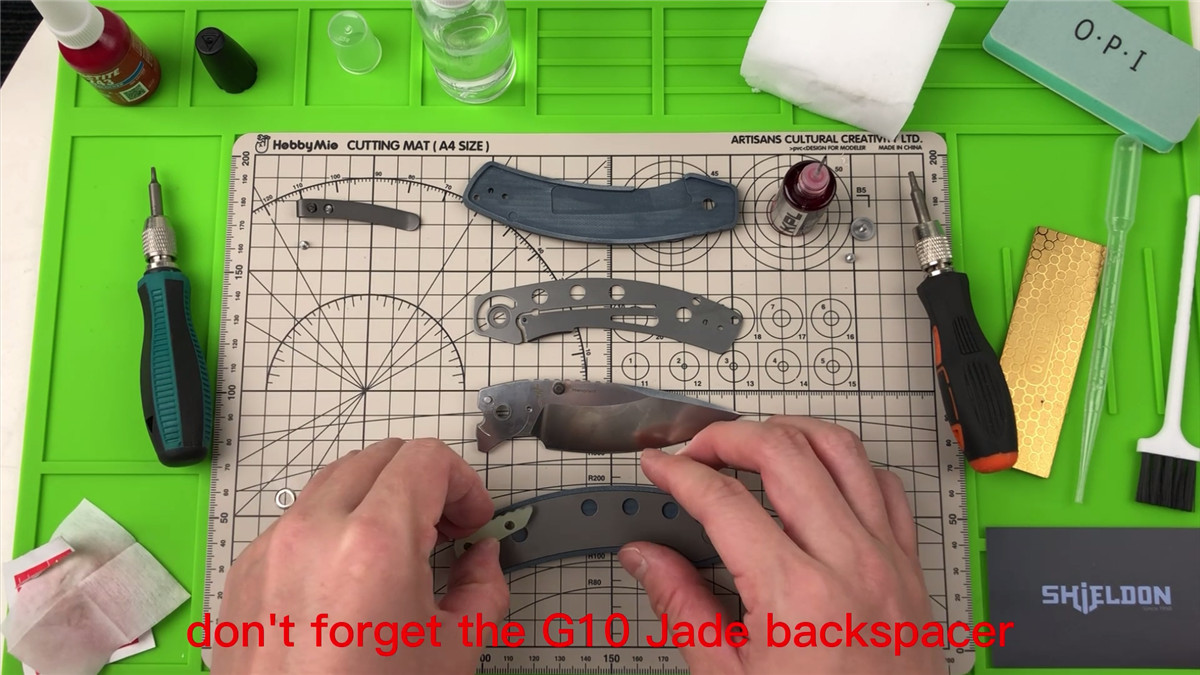

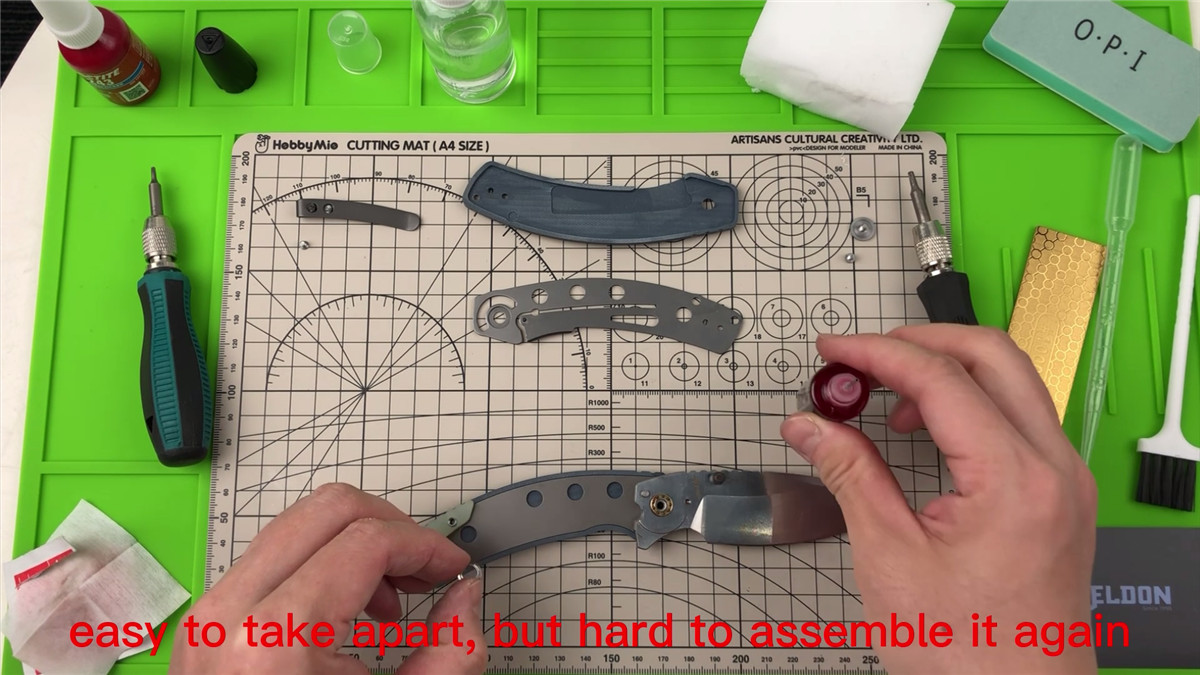

Reassembly: The Basics of the Shieldon Hierophant

Centralizing the Pivot in Reassembly

In the reassembly of the Shieldon Hierophant, the pivot screw is more than just a fastener; it's the central axis of the knife's operation. As the heart of the knife, it must be aligned perfectly to ensure a smooth opening and closing motion. It's crucial to apply the right amount of torque to the T8 pivot screw: too loose and the blade may wobble; too tight and you'll hinder the deployment action. The use of a reliable T8 screwdriver, as recommended by Shieldon, ensures each enthusiast can perform this with ease, maintaining the sleek operation facilitated by the caged ceramic ball bearings.

The Necessity of Complete Component Inclusion

Every piece

of the Hierophant is essential – from the satin-finished 154CM blade to the

honeydew and jade G10 handle scales. During reassembly, it's vital to include

all components, such as the nested liner lock that provides an extra layer of

safety and the pocket clip for convenient carry. Neglecting even a single

washer or standoff can impact the knife's functionality, showing that the

designer Matthew Szymanski's attention to detail is not just for aesthetics but

for the practical integrity of the knife.

Washer Placement for Optimal Functionality

The placement of the washers in the Hierophant is a subtle but significant step in the reassembly process. These thin components may seem inconsequential, but they shield the pivot from the wear caused by the ceramic ball bearings' friction. Ensuring these washers are correctly positioned is critical; it guarantees that the knife will operate smoothly for thousands of cycles. It's a testament to Shieldon's commitment to durability – they provide the washers to protect your investment from the outset.

Reassembling

the Shieldon Hierophant not only reinforces the knife's physical integrity but

also affirms the user's connection to the tool. Each component, skillfully

secured back into place, ensures that the Hierophant remains a reliable,

lightweight companion for all EDC tasks. By following these basic principles of

reassembly, users guarantee the Hierophant's continued performance and uphold

the high-end experience that Shieldon promises with every product.

Fine-Tuning and Adjustments for the Shieldon Hierophant

Smooth Operation through Lubrication

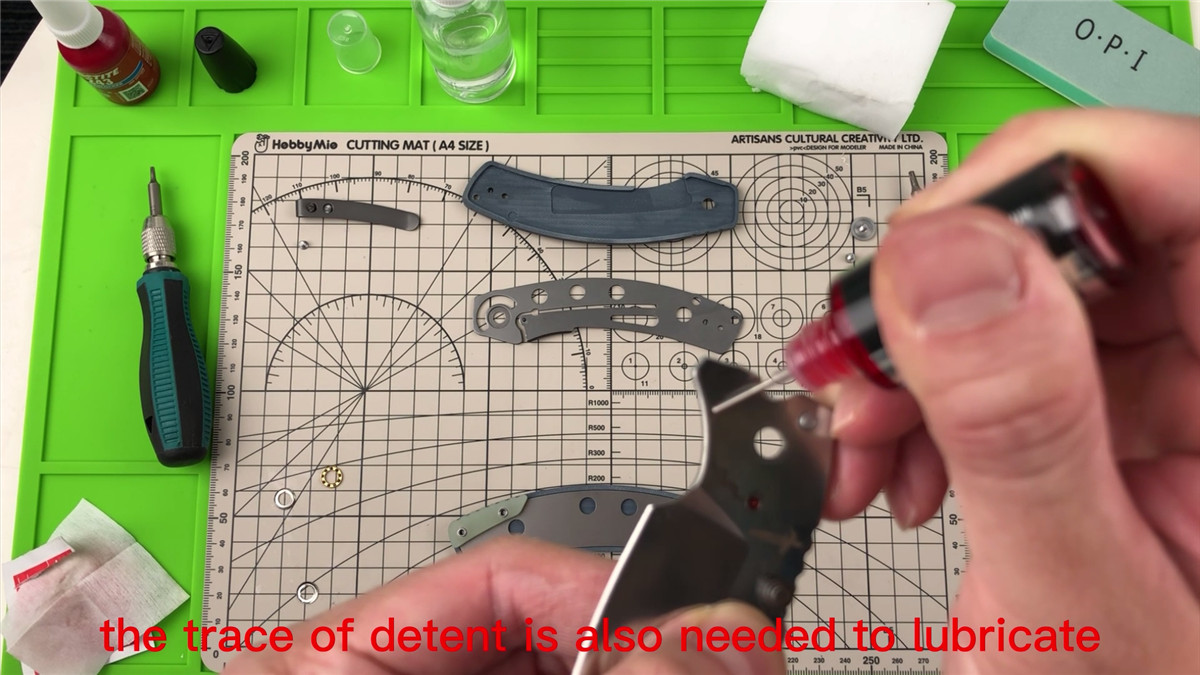

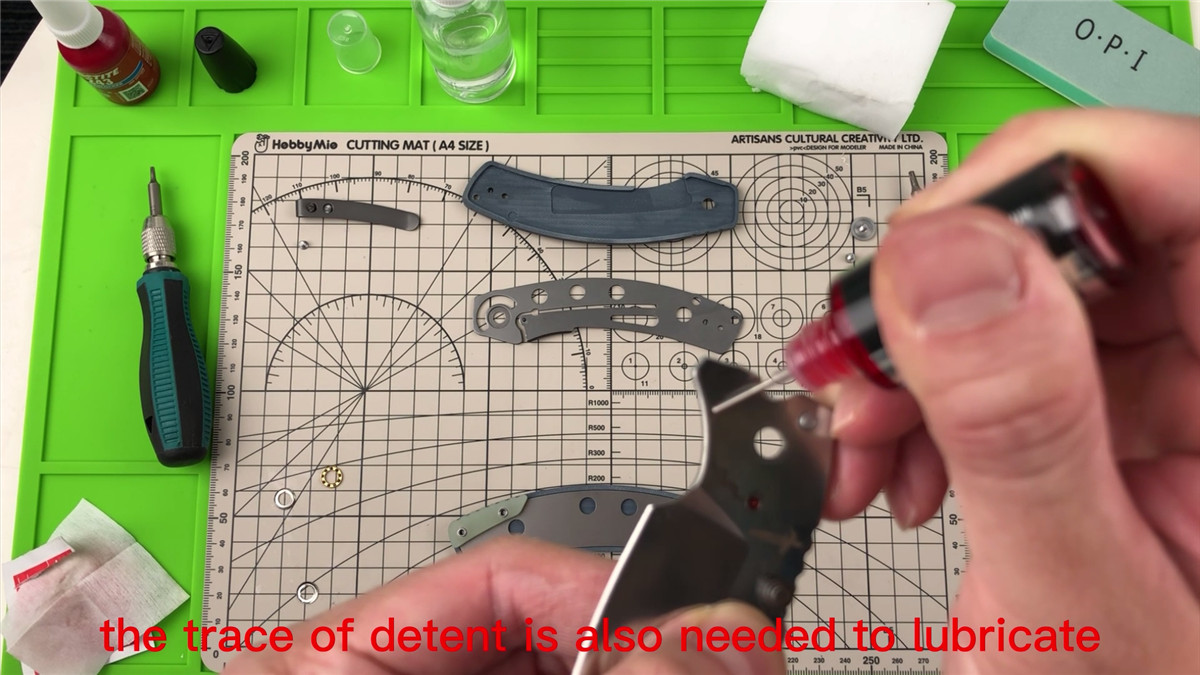

A smooth open-and-close experience is paramount for any EDC knife, and the Shieldon Hierophant is no exception. After reassembly, applying lubrication to the pivot ensures that the caged ceramic ball bearings operate without resistance. A high-quality knife pivot lubricant, such as KPL (Knife Pivot Lube), is recommended to maintain the smooth action. Just a few drops around the bearing and detent area can make a significant difference in deployment and retraction efficiency, enhancing the user experience of this Matthew Szymanski-designed tool.

Tackling Reassembly Challenges

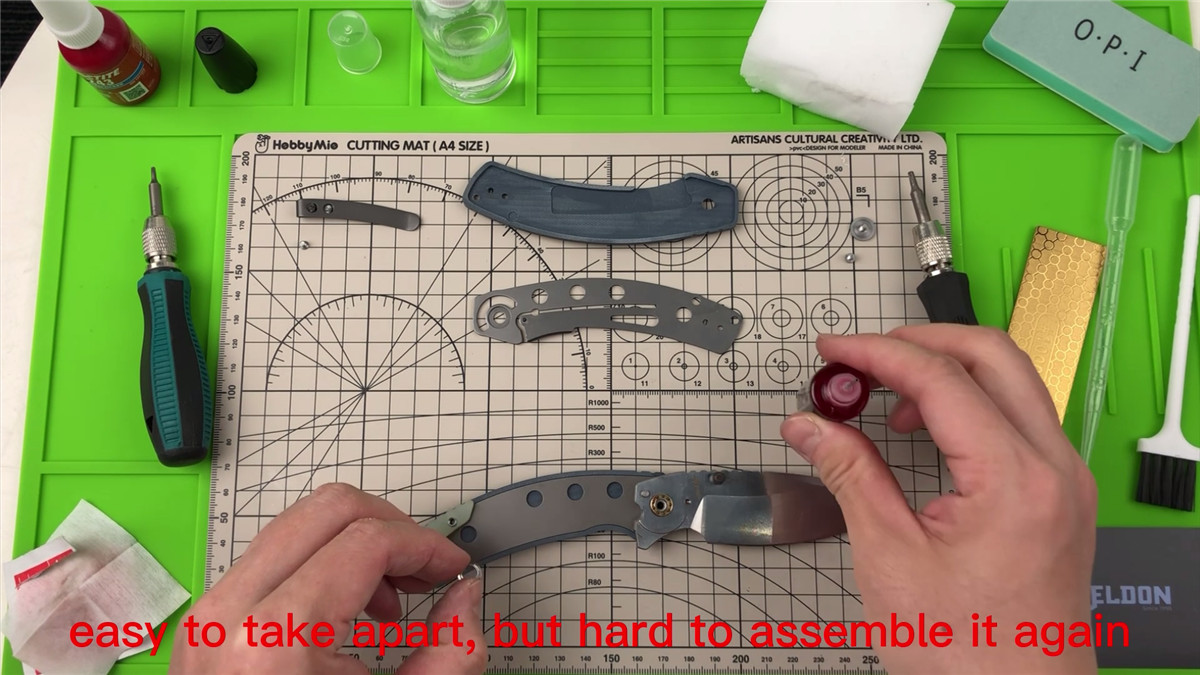

Upon

reassembling the Hierophant, enthusiasts may encounter common challenges such

as screw misalignment or tension issues. It's important to address these

patiently. For instance, if the pivot screw feels too tight or too loose, it

requires a delicate balance to adjust without affecting the blade's movement.

Using the T8 and T6 screwdrivers, make incremental adjustments to achieve the

perfect tension. This attention to detail reflects the fine craftsmanship of

Shieldon's stellar designs, including the precision required for the 154CM

blade and the striking Double G10 handle.

Perfecting Blade Centering

Achieving perfect blade centering is crucial for the Hierophant's functionality. If the blade is off-center, it could lead to uneven wear and tear or hinder the nested liner lock mechanism. The method for centering the blade involves a careful adjustment of the pivot screw. Turn it incrementally and check the blade's alignment after each tweak. This process not only ensures the blade is properly centered within the handle but also embodies the user's personal touch to their Hierophant, aligning it with Shieldon's vision of delivering a high-end, user-tuned experience for EDC aficionados.

The

Hierophant, with its lightweight design and the divine inspiration behind its

color scheme, is more than just a knife; it's a testament to careful design and

utility. Through fine-tuning and adjustments post-reassembly, users can ensure

that their Shieldon knife operates at peak performance. This fine-tuning

process underlines the EDC knife's role as a reliable tool for everyday tasks,

showcasing the blend of artistry and functionality that Shieldon and designer

Matthew Szymanski bring to the table.

Final Checks and Quality Control for the Shieldon Hierophant

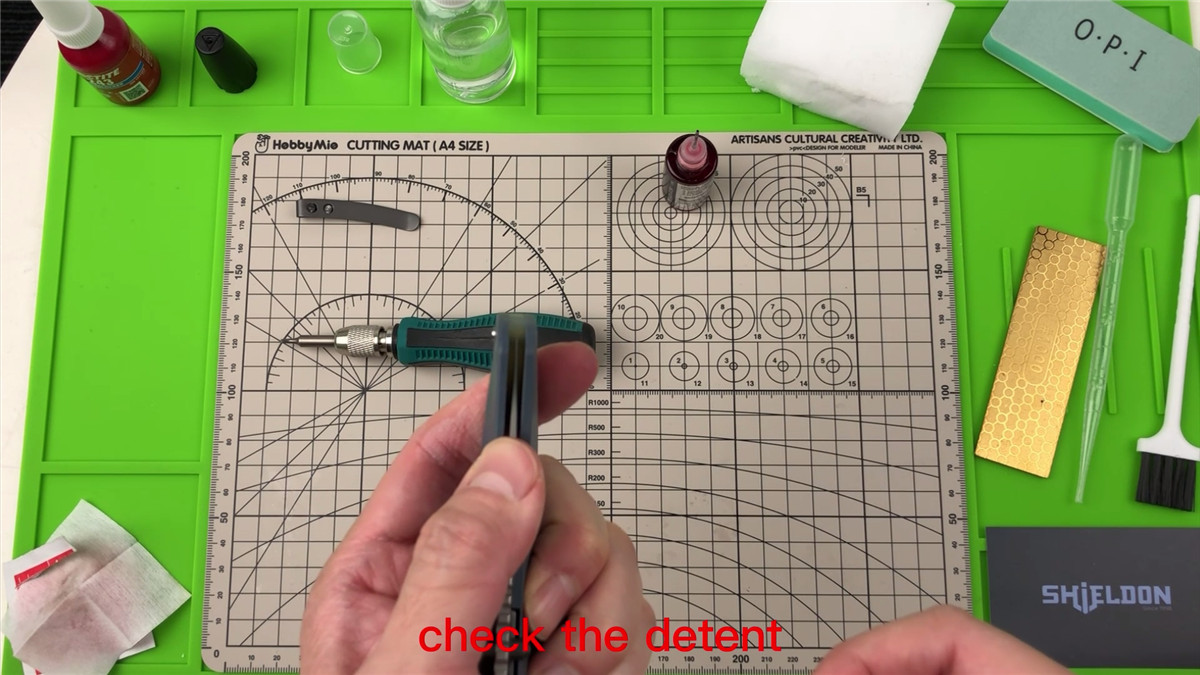

Ensuring Detent Strength and Blade Stability

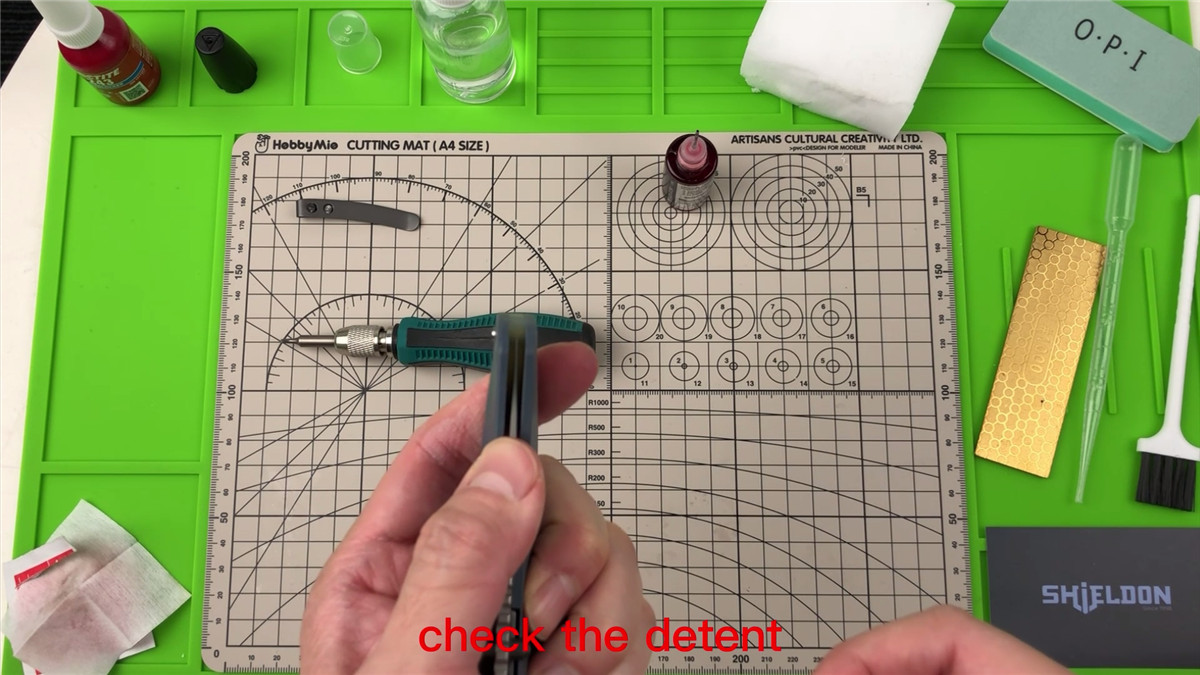

As the assembly of the Shieldon Hierophant concludes, a crucial step is to verify the detent strength, which contributes to the knife's secure locking mechanism. The detent must provide enough resistance to keep the blade safely in place while closed, yet not so much as to hinder a smooth deployment. This balance is achieved through the skillful design of Matthew Szymanski and the use of quality materials such as ceramic for the detent ball. Blade play is another aspect to check; the blade should not wobble side to side, ensuring precision in every cut with the robust 154CM steel blade.

Confirming Lock Security

The

integrity of the nested liner lock is paramount for safe operation. There

should be no lock rock—movement of the blade in the open position—which could

compromise safety and cutting accuracy. The Hierophant's liner lock is designed

for consistent and reliable performance, a prime example of Shieldon's

commitment to blending practicality with the cutting-edge design, inspired by

the symbolic wisdom and authority of its namesake.

Assessing Clip Position and Ergonomics

Finally, the position and comfort of the pocket clip are assessed. The Hierophant features a 95% deep carry tip-up clip, thoughtfully designed to reduce visibility for discreet carry and ensure comfort when extracting from the pocket. During quality control, it's confirmed that the clip does not create hot spots or discomfort in hand, further showcasing Shieldon's attention to detail. The ease of extracting the Hierophant from one's pocket highlights the practical everyday carry (EDC) design philosophy that Shieldon adheres to, emphasizing both form and function.

The

Hierophant, with its lightweight design, drop point blade, and unique color

palette, transcends being a mere tool; it represents the convergence of

aesthetic beauty and peak functionality. Each final check ensures that the

knife not only meets the high standards set by Shieldon but also exceeds the

expectations of knife enthusiasts worldwide, making it a staple in any EDC

collection. This meticulous quality control is a testament to Shieldon's

dedication to excellence and their commitment to delivering a knife that is

both a work of art and a reliable tool.

Showcasing the Reassembled Hierophant: A Triumph of Craftsmanship

Displaying the Fully Assembled Hierophant

The completion of the reassembly process brings the Shieldon Hierophant back to its full glory. Every curve of the satin-finished blade, the precision of the nested liner lock, and the distinctive hue of the honeydew and jade G10 handle – all come together to epitomize the knife's design philosophy inspired by Greek myths. The Hierophant stands as a testament to both its designer, Matthew Szymanski's vision, and Shieldon's commitment to quality in the EDC knife industry.

The Satisfaction of Successful Reassembly

There is a

unique satisfaction that comes with the successful reassembly of an EDC knife,

particularly one as refined as the Hierophant. The alignment of each component,

down to the last T6 clip screw, is a nod to the user's skill and patience.

Achieving the perfect tension in the pivot, confirming the blade is centered,

and feeling the secure snap of the nested liner lock – these are the moments

that affirm the craft of knife maintenance.

Tips for Maintaining Optimal Performance

To ensure

the Hierophant remains in peak condition, here are a few additional tips:

- After cleaning, apply a

high-grade lubricant to the pivot area and detent track to maintain the

smooth action for which the ceramic ball bearings are renowned.

- Regularly check the tension in

the screws, especially after extensive use, as they can become loose over

time.

- Sharpen the blade when

necessary, maintaining the 15-20 degree angle to preserve the blade's

integrity and cutting efficiency.

- Store the knife in a dry

environment to prevent corrosion and ensure the longevity of the 154CM

steel.

The Hierophant, after reassembly, is not just a tool; it's a companion for those who appreciate a knife that blends functionality with an aura of significance. Lightweight yet durable, practical yet with an inspired design, the reassembled Hierophant is ready to face everyday tasks with the assurance of Shieldon quality, making it an essential piece in any EDC collection.

Embrace the Hierophant: Your Next EDC Essential

Acquire the Precision-Crafted Shieldon Hierophant

Ready to

elevate your EDC collection? The Shieldon Hierophant, with its 154CM blade and

iconic Double G10 handle, awaits your grasp. Designed by the renowned Matthew

Szymanski, this knife is not just a utility tool but a piece of modern art

inspired by Greek mythology.

Exclusive Promotional Offer

For a limited time, use the promotional code "IW477WNO" when purchasing the Hierophant on Amazon to receive a 20% discount. Act swiftly, as this offer is as sharp as the blade itself and won't last forever.

Join the Community of Knife Aficionados

When you

choose Shieldon, you're not just buying a knife; you're becoming part of a

community that values exceptional design and quality. Visit Shieldon's website to explore more and connect with fellow enthusiasts. Whether

you're seeking maintenance tips, customer support, or just to share your

experience with the Hierophant, Shieldon welcomes you to the fold. Secure your

Hierophant today and become a part of our story.

Harnessing Mastery: The Hierophant's Role in EDC Culture

Reflecting on the Hierophant's Impact

The Shieldon Hierophant stands as a beacon in the EDC world, exemplifying how a deep understanding of one's tools enriches daily life. With its sleek 154CM blade and exquisite Honeydew and Jade G10 handle, it's more than just a knife—it's an extension of the carrier's will and a symbol of preparedness and finesse.

The Importance of Knowing Your Blade

Delving into the Hierophant's assembly is more than technical prowess; it's about forging a personal connection with your knife. This understanding enhances the user experience, imbuing every slice with confidence and every carry with pride.

A Community Built on Excellence

We invite you to share your experiences, offer feedback, and ask questions. Your insights help sharpen our craft, ensuring the Shieldon Hierophant continues to cut above the rest in both performance and significance. Join us in this journey of precision, passion, and perfection.

Mastering the Art of the Shieldon Hierophant: Disassembly and Reassembly Guide

Introduction: Embracing the Craft of EDC Knives with the Shieldon

Hierophant

The Surge of EDC Knives in Modern Culture

Every Day Carry (EDC) knives have surged in popularity as symbols of self-reliance and craftsmanship. These compact, functional tools are not just accessories but extensions of one's personal style and preparedness. With a market that's rapidly expanding, enthusiasts are not only keen on owning EDC knives but also on understanding their intricate mechanics.

The Shieldon Hierophant: A Fusion of Art and Utility

Enter the

Shieldon Hierophant, a masterpiece from the creative mind of Matthew Szymanski.

This EDC knife is a seamless blend of utility and aesthetics, designed to cater

to both knife aficionados and daily users. With a 154CM blade known for its

resilience and a double G10 handle that provides a secure grip, the Hierophant

stands as a pinnacle of modern knife-making. The nested liner lock and ceramic

ball bearings ensure smooth deployment, while the design — inspired by Greek

mythology — imbues it with a narrative as rich as its functionality.

Mastery in Maintenance: Disassembly and Reassembly Skills

Understanding

the disassembly and reassembly of the Hierophant isn't just about maintenance;

it's about deepening the connection between the knife and its owner. It's a

skill that transforms users from passive carriers to active participants in the

life of their knife. Disassembling allows for a comprehensive cleaning,

essential upkeep, and the option to customize, making it a critical skill for

any serious EDC carrier.

Through this

article, we'll explore the meticulous process of breaking down and rebuilding

the Shieldon Hierophant. We'll delve into the thoughtful engineering behind

each component, the practical beauty of its design philosophy, and the

satisfying journey from disassembly to a well-earned reassembly. Whether you're

a seasoned collector or a newcomer to the world of EDC, mastering these skills

will elevate your experience beyond the mere act of carrying a knife.

Unveiling the Shieldon Hierophant: Where Elegance Meets Precision

A Crafted Piece of EDC Excellence

The Shieldon

Hierophant, item MS01A from the Crusader segment, is not just any EDC knife;

it's a meticulously crafted tool designed by the renowned Matthew Szymanski.

This knife encompasses balance, strength, and a lightweight design, weighing in

at just 4.27 oz (121g), making it significantly lighter than other knives of

similar size. With a blade forged from 154CM steel, known for its exceptional

edge retention and corrosion resistance, the Hierophant boasts a flat grind and

a satin finish, presenting a perfect blend of performance and visual appeal.

Design Ingenuity of Matthew Szymanski

Matthew

Szymanski's design philosophy marries functionality with a nod to ancient

wisdom, as seen in the Hierophant's name and theme. His approach to using

low-end materials to initially introduce the design to the market is a

testament to Shieldon's confidence in delivering high-end quality. The unique

color palette of honeydew and jade on the G10 handle not only sets this knife

apart aesthetically but also aligns with the Hierophant theme, borrowing its

name and symbolic significance from the Greek myths.

Key Features and Selling Points

The Hierophant's drop point blade is a classic choice for EDC, offering versatility for daily tasks with a 15-20 degree sharpened angle right out of the box. This level of readiness is a testament to Shieldon's commitment to user satisfaction from the first cut. The blade's swedge enhances its beauty and balance, while the satin finish reduces glare, providing a discreet yet stylish appearance.

The double

G10 handle is robust, designed for enduring use, and the nested liner lock

mechanism ensures the blade stays secure when in use. The engineering

thoughtfulness extends to the assembly hardware, using T8 screws for most of

the knife, simplifying maintenance tasks for the user. The pocket clip is

nearly full deep carry, designed for a low profile in the pocket, and is

complemented by the smooth action of a caged ceramic ball-bearing system.

The Hierophant's disassembly and assembly are as elegant as its design, with Shieldon opting for non-glued screws, a decision driven by user feedback for ease of maintenance. Each step, from the strategic placement of the T6 screws to the skeletonized liners for weight reduction, showcases Shieldon's dedication to detailed craftsmanship.

Embrace the

Hierophant for its exceptional design, user-friendly maintenance, and the story

it carries with every slice — a true testament to Shieldon's vision of

combining classic mythology with modern EDC functionality.

Preparing for Disassembly: Laying the Groundwork for Your Shieldon

Hierophant

The Essential Step of Proper Disassembly

Before diving into the intricacies of the Shieldon Hierophant, it's crucial to understand the value of proper disassembly. Disassembling your EDC knife is not just about taking it apart but doing so in a way that ensures every component remains intact and functional upon reassembly. This careful process allows for thorough cleaning, maintenance, and the occasional upgrade, extending the knife's lifespan and keeping it in optimal working condition.

Gathering Your Toolkit

To

disassemble the Shieldon Hierophant, you'll need the right tools for the job.

Thankfully, this knife's design considers the user's convenience; requiring

only two types of screwdrivers for the task — T8 for the main pivot and handle

body, and T6 for the pocket clip. Having the correct tools ensures that you

won’t strip the screws or damage your knife, allowing for a smooth and

efficient maintenance experience.

Considerations and Precautions Before You Begin

Before you start, it's imperative to work in a clean, well-lit area where small parts are less likely to get lost. Ensure your workspace is free from clutter and potential contaminants. Remember that the Hierophant's screws are no longer glued, as per Shieldon's response to consumer feedback, making the disassembly a user-friendly experience. However, it's still vital to proceed with caution to avoid misplacing any components or disrupting the delicate balance of the assembly.

When

disassembling your knife, be mindful of the blade's edge. The Hierophant's

154CM steel blade is sharpened to a 15-20 degree angle, offering superb

out-of-the-box usability that you'll want to maintain. Take care not to dull

the edge as you work. Approach each step with respect for the design and

craftsmanship that Matthew Szymanski has instilled in this tool — from its

lightweight, durable double G10 handle to its smooth ceramic ball-bearing

deployment mechanism.

In preparing to disassemble your Shieldon Hierophant, you're not just taking apart a knife; you're engaging with a process that's as much about care and precision as it is about practicality. It's an opportunity to appreciate the knife's design, reflect on its symbolic connection to Greek mythology, and ensure you're equipped to keep your Hierophant in peak condition for years to come.

Step-by-Step Disassembly Process of the Shieldon Hierophant

Mastering the Pivot Screw: Techniques for Success

The pivot

screw is the linchpin of the Shieldon Hierophant's folding mechanism, and its

unscrewing is a crucial first step in the disassembly process. Armed with a T8

screwdriver, approach this task with precision. Here's a pro-tip: apply gentle

pressure and turn slowly to avoid stripping the screw. The pivot should be

unscrewed before addressing any other hardware, as this will ensure the blade

and handle are not under tension, reducing the risk of accidental injury or

damage.

The 'Shield'-Like Screw and Its Unique Design

Designed to prevent the pivot from rotating during maintenance, the 'shield'-like screw on the showside is an innovative feature that sets the Hierophant apart. This design ensures that the screw on the reverse side remains stationary, allowing for a hassle-free disassembly. It's a testament to Shieldon's commitment to user-friendly products, echoing the thoughtful design philosophies of Matthew Szymanski.

The Elegant One-Screw Handle Design

Simplicity

is the essence of elegance, and the Hierophant embodies this with its one-screw

handle design. By using a single T8 screw on the handle, Shieldon has not only

created a sleek and minimalist aesthetic but also made maintenance an absolute

breeze for knife enthusiasts. This single screw architecture streamlines the

disassembly process, making it straightforward for owners to maintain their

Hierophant.

The Dual Functionality of T6 Screws

The T6 screws on the Shieldon Hierophant are a marvel of multifunctional design. While primarily securing the pocket clip, these screws also play a crucial role in attaching the liner to the handle. This dual-purpose approach minimizes the number of screws visible on the knife, maintaining the clean lines of the design and reducing potential weak points. It's a demonstration of Shieldon's commitment to efficient design and functionality, blending form with function in a way that resonates with the practical needs of EDC users.

The

disassembly of the Shieldon Hierophant is a journey through the meticulous

design and high-end craftsmanship of this EDC knife. With each screw and

component, users engage with the thoughtfulness put into the knife's creation.

By following these steps attentively, knife enthusiasts not only learn about

their tool's inner workings but also gain a deeper appreciation for the

expertise behind its assembly. Whether preparing for routine maintenance or

deep cleaning, these techniques ensure that your Hierophant remains a reliable

and elegant companion for all your daily adventures.

Exploring the Inner Workings of the Shieldon Hierophant

Delving into the Core: Liners, Bearings, and Backspacer

Once you unscrew the Hierophant's pivot and handle, you'll expose the intricate world inside. The skeletonized liners, a product of careful engineering, are vital for structural integrity while minimizing weight—a feature that contributes to the Hierophant's featherlike presence in your pocket. These liners are cut from 3Cr13 steel and treated to a hardness of 42-44 HRC, ensuring durability without unnecessary heft.

The caged

ceramic ball bearings are another highlight of Shieldon's design prowess. They

allow for a fluid, three-way deployment that's as satisfying to use as it is to

watch. And when it's time for reassembly, remember the tiny washers on either

side of these bearings protect your knife's pivot from wear over time, a subtle

nod to longevity in Shieldon's design ethos.

The Balancing Act: Weight and Material Selection

When handling the Hierophant, its lightweight nature is immediately apparent, tipping the scales at just 4.27 oz (121g). This is no accident but the result of deliberate choices in materials and design, such as the four weight-reduction holes in the liners. Each hole shaves off approximately 2g, contributing to the knife's overall nimbleness. It's this kind of attention to detail that defines the Shieldon Hierophant and sets it apart from its peers.

The Backbone of Stability: The Role of Standoffs

Venturing

further into the Hierophant's anatomy reveals the robust standoffs, providing a

standoff between the handle scales even when the Jade G10 backspacer is

removed. These standoffs are constructed from 416 steel, chosen for its

strength, and contribute to the knife's solid feel in hand. They are the unsung

heroes of the knife's stability, ensuring that the integrity of the knife's frame

is uncompromised, regardless of the backspacer's presence.

In exploring the interior of the Shieldon Hierophant, one not only gains insight into the knife's functional aspects but also uncovers the narrative of its construction. The careful balancing of weight, the strategic choice of materials, and the thoughtful inclusion of standoffs—all speak to Shieldon's dedication to creating not just a cutting tool but a piece of EDC artistry. As you learn to dismantle and reassemble this knife, you become part of its story, a testament to the harmony between user and tool.

Disassembly: A Closer Look at the Components of the Shieldon Hierophant

Diving Deep into Each Element

When you

disassemble the Shieldon Hierophant, you're not just taking apart a knife; you

are uncovering the meticulous craftsmanship of each component. Starting with

the 154CM blade, a premium steel known for its remarkable edge retention and

corrosion resistance, you can appreciate the flat grind which offers an ideal

balance between sharpness and strength. This blade, enhanced by a drop point

and a subtle swedge, is not only functional for EDC tasks but also resonates

with the knife's aesthetic appeal.

The double G10 handle, known for its durability and excellent grip, is a significant contributor to the Hierophant's lightweight profile. Its honeydew and jade colors are not just distinctive design choices; they also provide a visual representation of the Hierophant's divine inspiration. The nested liner lock within this handle is a testament to Shieldon's commitment to safety and efficiency.

Significance in Everyday Carry Utility

Each part of

the Hierophant is designed with EDC utility in mind. The main pivot hardware,

accessible with a T8 screwdriver, is a crucial point for the knife's smooth

operation, allowing for flipper or thumb stud deployment. The inclusion of

caged ceramic ball bearings ensures this action remains as smooth on the

thousandth open as it was on the first.

The deep carry tip-up pocket clip design is not an afterthought; it's a feature that enhances the practicality of carrying the knife discreetly and securely. The clip's half deep carry design, a unique innovation from Shieldon, addresses a common concern among EDC users, ensuring that the Hierophant can be quickly and comfortably accessed when needed.

Understanding the Role of Each Part

Every screw,

liner, and standoff has its role. The T6 screws serve dual functions, securing

both the pocket clip and the liner, a clever design choice that simplifies the

knife’s profile without sacrificing functionality. Upon disassembly, the

significance of these screws becomes clear, showcasing the designer's attention

to detail and practical innovation.

The backspacer, which may seem like a mere aesthetic addition, plays a crucial role in maintaining the structural spacing between the handle scales. Even the standoffs, though small, are pivotal in preserving the knife's stability and ensuring that the knife remains functional and reliable, no matter the conditions.

Disassembling

the Hierophant not only provides you with the skills to maintain and clean your

knife but also offers a deeper appreciation for each element and its role in

the overall performance and utility of the knife. Shieldon’s Hierophant is a

masterpiece of EDC design, where each component is a piece of the puzzle that

creates an exceptional everyday carry experience. Through this detailed

examination, enthusiasts and users alike can recognize the profound thought and

expertise that goes into constructing a knife that's not only a tool but a

partner in the daily adventures of life.

Cleaning and Maintenance of the Shieldon Hierophant

Ensuring Longevity Through Proper Techniques

Maintaining your Shieldon Hierophant isn't just about keeping it looking good—it's crucial for ensuring its longevity and functionality. For a thorough clean, begin by wiping down the 154CM blade, famed for its edge retention, with a soft cloth and a mild detergent. Use a brush to gently scrub the satin-finish surface, being careful to preserve the lines on the bevel that reduce glare and enhance the knife's aesthetics.

The Double

G10 handle, notable for its two-tone honeydew and jade colorway, demands a

careful approach. Dirt can be removed from the textured surface with a

toothbrush or a specialized cleaning tool designed for G10 material. This

prevents buildup that could compromise grip over time.

Frequency and Importance of Knife Care

A common query among EDC enthusiasts is the frequency of maintenance. The Hierophant, with its nested liner lock and ceramic ball bearings, should ideally be cleaned every three months or more depending on usage. Regular care prevents grime accumulation and ensures each deployment is as smooth as the first—a cornerstone of the Hierophant's design by Matthew Szymanski.

Products to Keep Your Hierophant in Top Condition

When it

comes to products for keeping your Hierophant in optimal condition, consider

investing in quality lubricants like KPL (Knife Pivot Lube) to maintain the

smooth action of the ball bearings. For the blade, a high-quality knife oil can

prevent rust and corrosion, especially after cleaning with water.

For the handle, a G10 cleaner can restore the grip's texture and color vibrancy. Tuf-Glide or Loctite can be used on screws post-cleaning to ensure they stay in place without being overly tight. Furthermore, a rust inhibitor such as Rusty's Rags can protect the blade when the knife is stored for extended periods.

Regular

maintenance is an opportunity to understand your Hierophant's workings

intimately. Each screw, pivot, and clip is a testament to Shieldon's dedication

to quality, and by caring for these components, you honor the craftsmanship and

ensure that your knife stands the test of time and use. The Hierophant isn't

just a tool—it's a companion on your daily adventures, and with proper care, it

will remain reliable and efficient, much like the wisdom of its namesake, the

Hierophant of Greek myth.

Reassembly: The Basics of the Shieldon Hierophant

Centralizing the Pivot in Reassembly

In the reassembly of the Shieldon Hierophant, the pivot screw is more than just a fastener; it's the central axis of the knife's operation. As the heart of the knife, it must be aligned perfectly to ensure a smooth opening and closing motion. It's crucial to apply the right amount of torque to the T8 pivot screw: too loose and the blade may wobble; too tight and you'll hinder the deployment action. The use of a reliable T8 screwdriver, as recommended by Shieldon, ensures each enthusiast can perform this with ease, maintaining the sleek operation facilitated by the caged ceramic ball bearings.

The Necessity of Complete Component Inclusion

Every piece

of the Hierophant is essential – from the satin-finished 154CM blade to the

honeydew and jade G10 handle scales. During reassembly, it's vital to include

all components, such as the nested liner lock that provides an extra layer of

safety and the pocket clip for convenient carry. Neglecting even a single

washer or standoff can impact the knife's functionality, showing that the

designer Matthew Szymanski's attention to detail is not just for aesthetics but

for the practical integrity of the knife.

Washer Placement for Optimal Functionality

The placement of the washers in the Hierophant is a subtle but significant step in the reassembly process. These thin components may seem inconsequential, but they shield the pivot from the wear caused by the ceramic ball bearings' friction. Ensuring these washers are correctly positioned is critical; it guarantees that the knife will operate smoothly for thousands of cycles. It's a testament to Shieldon's commitment to durability – they provide the washers to protect your investment from the outset.

Reassembling

the Shieldon Hierophant not only reinforces the knife's physical integrity but

also affirms the user's connection to the tool. Each component, skillfully

secured back into place, ensures that the Hierophant remains a reliable,

lightweight companion for all EDC tasks. By following these basic principles of

reassembly, users guarantee the Hierophant's continued performance and uphold

the high-end experience that Shieldon promises with every product.

Fine-Tuning and Adjustments for the Shieldon Hierophant

Smooth Operation through Lubrication

A smooth open-and-close experience is paramount for any EDC knife, and the Shieldon Hierophant is no exception. After reassembly, applying lubrication to the pivot ensures that the caged ceramic ball bearings operate without resistance. A high-quality knife pivot lubricant, such as KPL (Knife Pivot Lube), is recommended to maintain the smooth action. Just a few drops around the bearing and detent area can make a significant difference in deployment and retraction efficiency, enhancing the user experience of this Matthew Szymanski-designed tool.

Tackling Reassembly Challenges

Upon

reassembling the Hierophant, enthusiasts may encounter common challenges such

as screw misalignment or tension issues. It's important to address these

patiently. For instance, if the pivot screw feels too tight or too loose, it

requires a delicate balance to adjust without affecting the blade's movement.

Using the T8 and T6 screwdrivers, make incremental adjustments to achieve the

perfect tension. This attention to detail reflects the fine craftsmanship of

Shieldon's stellar designs, including the precision required for the 154CM

blade and the striking Double G10 handle.

Perfecting Blade Centering

Achieving perfect blade centering is crucial for the Hierophant's functionality. If the blade is off-center, it could lead to uneven wear and tear or hinder the nested liner lock mechanism. The method for centering the blade involves a careful adjustment of the pivot screw. Turn it incrementally and check the blade's alignment after each tweak. This process not only ensures the blade is properly centered within the handle but also embodies the user's personal touch to their Hierophant, aligning it with Shieldon's vision of delivering a high-end, user-tuned experience for EDC aficionados.

The

Hierophant, with its lightweight design and the divine inspiration behind its

color scheme, is more than just a knife; it's a testament to careful design and

utility. Through fine-tuning and adjustments post-reassembly, users can ensure

that their Shieldon knife operates at peak performance. This fine-tuning

process underlines the EDC knife's role as a reliable tool for everyday tasks,

showcasing the blend of artistry and functionality that Shieldon and designer

Matthew Szymanski bring to the table.

Final Checks and Quality Control for the Shieldon Hierophant

Ensuring Detent Strength and Blade Stability

As the assembly of the Shieldon Hierophant concludes, a crucial step is to verify the detent strength, which contributes to the knife's secure locking mechanism. The detent must provide enough resistance to keep the blade safely in place while closed, yet not so much as to hinder a smooth deployment. This balance is achieved through the skillful design of Matthew Szymanski and the use of quality materials such as ceramic for the detent ball. Blade play is another aspect to check; the blade should not wobble side to side, ensuring precision in every cut with the robust 154CM steel blade.

Confirming Lock Security

The

integrity of the nested liner lock is paramount for safe operation. There

should be no lock rock—movement of the blade in the open position—which could

compromise safety and cutting accuracy. The Hierophant's liner lock is designed

for consistent and reliable performance, a prime example of Shieldon's

commitment to blending practicality with the cutting-edge design, inspired by

the symbolic wisdom and authority of its namesake.

Assessing Clip Position and Ergonomics

Finally, the position and comfort of the pocket clip are assessed. The Hierophant features a 95% deep carry tip-up clip, thoughtfully designed to reduce visibility for discreet carry and ensure comfort when extracting from the pocket. During quality control, it's confirmed that the clip does not create hot spots or discomfort in hand, further showcasing Shieldon's attention to detail. The ease of extracting the Hierophant from one's pocket highlights the practical everyday carry (EDC) design philosophy that Shieldon adheres to, emphasizing both form and function.

The

Hierophant, with its lightweight design, drop point blade, and unique color

palette, transcends being a mere tool; it represents the convergence of

aesthetic beauty and peak functionality. Each final check ensures that the

knife not only meets the high standards set by Shieldon but also exceeds the

expectations of knife enthusiasts worldwide, making it a staple in any EDC

collection. This meticulous quality control is a testament to Shieldon's

dedication to excellence and their commitment to delivering a knife that is

both a work of art and a reliable tool.

Showcasing the Reassembled Hierophant: A Triumph of Craftsmanship

Displaying the Fully Assembled Hierophant

The completion of the reassembly process brings the Shieldon Hierophant back to its full glory. Every curve of the satin-finished blade, the precision of the nested liner lock, and the distinctive hue of the honeydew and jade G10 handle – all come together to epitomize the knife's design philosophy inspired by Greek myths. The Hierophant stands as a testament to both its designer, Matthew Szymanski's vision, and Shieldon's commitment to quality in the EDC knife industry.

The Satisfaction of Successful Reassembly

There is a

unique satisfaction that comes with the successful reassembly of an EDC knife,

particularly one as refined as the Hierophant. The alignment of each component,

down to the last T6 clip screw, is a nod to the user's skill and patience.

Achieving the perfect tension in the pivot, confirming the blade is centered,

and feeling the secure snap of the nested liner lock – these are the moments

that affirm the craft of knife maintenance.

Tips for Maintaining Optimal Performance

To ensure

the Hierophant remains in peak condition, here are a few additional tips:

- After cleaning, apply a

high-grade lubricant to the pivot area and detent track to maintain the

smooth action for which the ceramic ball bearings are renowned.

- Regularly check the tension in

the screws, especially after extensive use, as they can become loose over

time.

- Sharpen the blade when

necessary, maintaining the 15-20 degree angle to preserve the blade's

integrity and cutting efficiency.

- Store the knife in a dry

environment to prevent corrosion and ensure the longevity of the 154CM

steel.

The Hierophant, after reassembly, is not just a tool; it's a companion for those who appreciate a knife that blends functionality with an aura of significance. Lightweight yet durable, practical yet with an inspired design, the reassembled Hierophant is ready to face everyday tasks with the assurance of Shieldon quality, making it an essential piece in any EDC collection.

Embrace the Hierophant: Your Next EDC Essential

Acquire the Precision-Crafted Shieldon Hierophant

Ready to

elevate your EDC collection? The Shieldon Hierophant, with its 154CM blade and

iconic Double G10 handle, awaits your grasp. Designed by the renowned Matthew

Szymanski, this knife is not just a utility tool but a piece of modern art

inspired by Greek mythology.

Exclusive Promotional Offer

For a limited time, use the promotional code "IW477WNO" when purchasing the Hierophant on Amazon to receive a 20% discount. Act swiftly, as this offer is as sharp as the blade itself and won't last forever.

Join the Community of Knife Aficionados

When you

choose Shieldon, you're not just buying a knife; you're becoming part of a

community that values exceptional design and quality. Visit Shieldon's website to explore more and connect with fellow enthusiasts. Whether

you're seeking maintenance tips, customer support, or just to share your

experience with the Hierophant, Shieldon welcomes you to the fold. Secure your

Hierophant today and become a part of our story.

Harnessing Mastery: The Hierophant's Role in EDC Culture

Reflecting on the Hierophant's Impact

The Shieldon Hierophant stands as a beacon in the EDC world, exemplifying how a deep understanding of one's tools enriches daily life. With its sleek 154CM blade and exquisite Honeydew and Jade G10 handle, it's more than just a knife—it's an extension of the carrier's will and a symbol of preparedness and finesse.

The Importance of Knowing Your Blade

Delving into the Hierophant's assembly is more than technical prowess; it's about forging a personal connection with your knife. This understanding enhances the user experience, imbuing every slice with confidence and every carry with pride.

A Community Built on Excellence

We invite you to share your experiences, offer feedback, and ask questions. Your insights help sharpen our craft, ensuring the Shieldon Hierophant continues to cut above the rest in both performance and significance. Join us in this journey of precision, passion, and perfection.

.png)

Leave your comment

Note: HTML is not translated!